POSITIONING EQUIPMENT WHITE PAPERS AND CASE STUDIES

POSITIONING EQUIPMENT NEWS

-

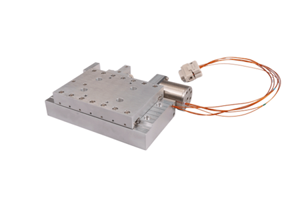

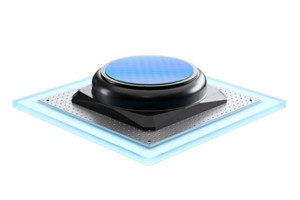

Announcing the P-545 PInano® piezo stage family, delivering nanometer-scale accuracy and high-speed motion control for high-resolution microscopy and material science applications.

-

High-speed nanometer-resolution piezo actuators and grippers are offered in a compact, lightweight design. These are ideal for various applications requiring precise, fast motion. These actuators are reliable, energy-efficient, and versatile.

-

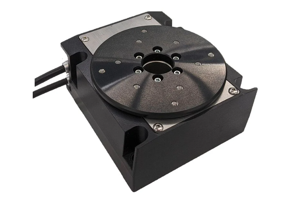

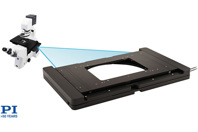

PI introduces the U-781 XY microscope stage, enhancing super-resolution fluorescence microscopy with 10nm resolution, ultrasonic piezo motors, and extensive software compatibility, all at an attractive price/performance ratio.

-

Global piezo nanopositioning leader PI introduces a new microscope stage family designed for democratizing the advantages of ultrasonic piezo motor drive systems in super-resolution fluorescence microscopy.

-

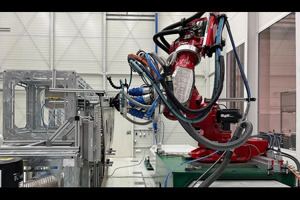

PI, the global leader in nanopositioning, ultra-precision motion control and piezo technology, has completed the construction of an additional manufacturing building at its Eschbach, Germany site.

-

New live demonstrations on air bearing stages, direct drive motorized motion systems, and sub-nanometer precision piezo stages backed by decades of PI’s nanopositioning experience.

-

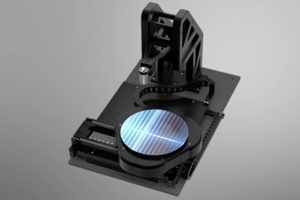

The PI Group continues its vertical integration strategy to provide a competitive advantage for customers while improving the odds of supply chain sustainability.

POSITIONING EQUIPMENT VIDEOS

-

Explore PPS capabilities for high-precision position measurements in semiconductor manufacturing, enabling advancements in lithography tools and system reliability with patented technologies.

-

PILightning tackles the first light capture issue in photonics alignment, promising dramatic improvements in testing and assembling photonic circuits, revolutionizing the industry.

-

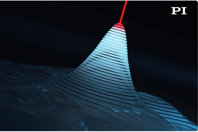

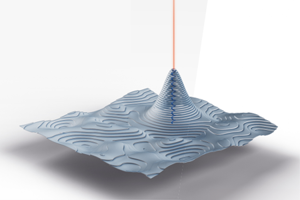

Combining piezo stages and linear motors can significantly improve micro-hole laser drilling performance. This demonstration looks at high-density 30µm micro-holes in glass.

-

Using optical sensors and gantry motion, 3D surface profiling is a technique that measures and analyzes the surface features of an object in 3D.

-

Compact air bearing stages provide superior dynamics in multi-axis automated optics and photonics alignment applications.

-

Silicon photonics is the most scalable and efficient approach to sustainably keep up with data demand. Motion control algorithms are important in reducing cycle times.

-

Peter J. de Groot gives a talk on interferometric precision positioning recorded live at the European Precision Engineering Society (euspen) Special Interest Group meeting on Precision Motion Systems & Control.