ABOUT ALLUXA

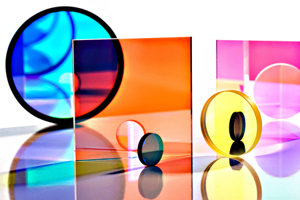

Alluxa (Santa Rosa, CA) designs and manufactures next generation, hard-coated optical filters using the proprietary SIRRUS Plasma Deposition Process. The sophisticated coating process provides precision wavelength control and uniform coatings, even for large-format parts. It also permits production of the same high-performance optical filters over multiple coating runs and in multiple chambers. Alluxa can produce thin-film coatings in a fraction of the time (compared to standard coating methods) and make automated adjustments to layer thicknesses and uniformity in real time – translating to higher performance and lower costs for our customers.

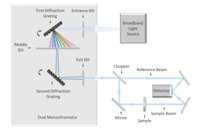

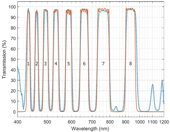

Our proprietary HELIX™ Spectral Analysis System has redefined measurement capabilities of high-performance thin-film optical filters to address the limitations of most commercially-available spectrophotometers. The system’s capabilities are four-fold: it is able to track filter edges to OD7 (-70 dB), evaluate blocking to OD9 (-90 dB), resolve edges as steep as 0.4% relative to edge wavelength from 90% transmission to OD7, and resolve passbands that are as narrow as 0.1 nm at full width half maximum (FWHM).

The company’s commitment to advanced metrology ensures that once coated, the performance of Alluxa optical filters is tested using state-of-the-art instruments. Optical filter transmission and blocking in the UV, VIS, and NIR are measured using one of the most advanced spectrophotometers on the market, and IR filters are measured using an FTIR spectrometer.

Alluxa’s unique, purpose-built deposition platform and control systems were designed, developed, and built by our in-house team to address the demanding requirements of the next generation of systems and instruments. We continue to dedicate a large amount of resources to research and development to meet our goals of increasing production capability and continuing to provide > 99% on-time delivery while creating the world’s most challenging filters at breakthrough price points.

Founded in 2007, Alluxa is an ISO 9001:2015 certified, ITAR registered manufacturer of high-performance optical filters and thin-film coatings.

WHY ALLUXA? PRECISION OPTICAL FILTERS AND THIN-FILM COATING

CONTACT INFORMATION

Alluxa, Inc.

3660 N. Laughlin Road

Santa Rosa, CA 95403

UNITED STATES

Phone: +1 855-425-5892

Contact: Peter Egerton, CCO

FEATURED ARTICLES

-

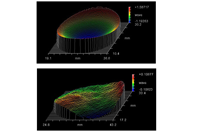

When interferometric testing isn’t possible, an analytical, spectral-based model predicts coating-contributed transmitted wavefront error with confidence, enabling compliance and control for advanced optical systems.

-

High-performance optical reflectors, introduce phase effects that cause spatial and temporal distortions. Understanding group delay, and polarization-dependent variations is crucial.

-

Discover how advancements in ultra-precise manufacturing techniques can pave the way for revolutionary technology that can change the world.

-

Understanding the mechanical dimensions of optical filters, particularly parameters like clear aperture and parallelism, is paramount for ensuring proper functionality.

-

Surface quality standards establish acceptable flaws on optical components that affect performance. Proper specification of these standards is crucial to achieving performance balance.

-

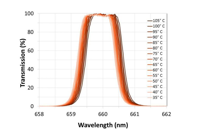

Thoughtful design and substrate selection are vital to minimize substantial shifts in interference filter spectra due to temperature fluctuations.

-

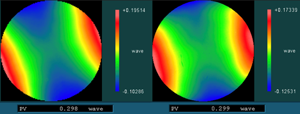

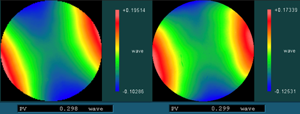

The concept of surface flatness and wavefront error in the context of optical components is explained, including how these properties are measured, defined, and how they impact optical performance.

-

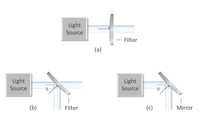

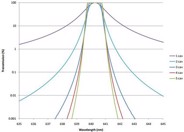

Cone half angle (CHA) measures the degree of convergence or divergence in an incident beam. Learn more about CHA and how it impacts optical filter spectra.

-

The relationship between angle of incidence (AOI) and polarization is explained, with a focus on how AOI affects the transmission and reflection of light.

-

Optical filters selectively transmit light in a particular range of wavelengths. The spectral features of optical filters are important for selecting the right filter for a particular application.

-

The COVID-19 pandemic has necessitated rapid and accurate quantitative analysis of dangerous pathogens. The “gold standard” for DNA detection today is quantitative polymerase chain reaction (qPCR). In this article, learn how thin film optics play a role in DNA detection.

-

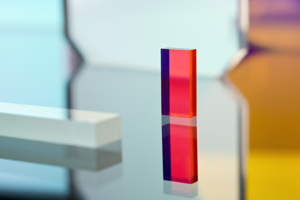

Alluxa’s proprietary high-speed plasma deposition technology delivers, for the first time, the optical performance and durability of hard-coated thin film optical filters at laminated soft coating prices.

-

Measuring the spectral response of advanced thin film optical filters is challenging, but can be overcome with the right approach.

-

Alluxa’s new class of ultra-narrow filters are designed for applications such as laser cleanup, lidar, telecommunications, and instrumentation. They also offer the narrowest and “squarest” filter profiles in the visible and NIR, as well as transmission levels that approach 100%.

-

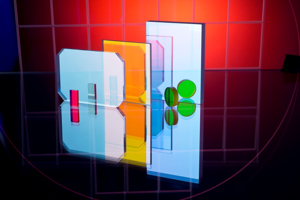

These filters are unique because they achieve flatness by eliminating the high stresses of a deposited traditional ion-based coating process such as ion beam sputtering (IBS) and ion assisted deposition (IAD).

-

Learn about different filter types, their key attributes, and how to optimize cost. The filters discussed include high cavity count band pass, replacement, tilted beamsplitter filters, and more.

-

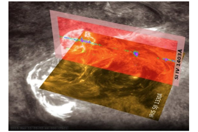

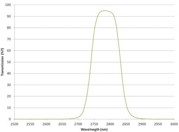

Alluxa’s new precision infrared bandpass and dual bandpass filter technology brings new levels of performance with higher transmissions, steeper slopes, and flatter pass bands than traditional evaporated coatings.

-

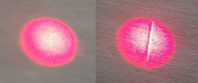

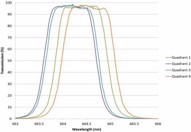

Narrowband filters are a critical technology for lidar, laser cleanup, chemical and gas sensing, and more. Because creating multicavity filters is a challenge for deposition process control systems, Alluxa uses a computer-controlled variation on the turning point method of thickness control for each individual layer.

-

Hard coated ultra-narrowband optical filters made using modern plasma processes offer much improved transmission, temperature stability and out of band blocking as compared to legacy soft coatings. These filters are used in optical systems as diverse as LIDAR (light detection and ranging), Doppler shift detection of plasma velocity, laser cleanup, chemical and gas sensing, as well as for cutting-edge astronomy and instrumentation applications.

-

Fluorescence-based systems have revolutionized the way organisms, cells, and biomolecules are visualized and detected. However, challenges common to these instruments, such as bleed-through, background autofluorescence, and poor signal-to-noise ratios, can reduce performance.

NEWS

-

Alluxa’s new Sirrus™ PVD process delivers ultra-flat, low-stress dichroic filters on thin substrates, enhancing optical performance for microscopy, medical, and space applications without compromising steep edges or high transmission.

-

Alluxa highlighted the company’s high-performance optical filters and thin-film coatings for the most demanding applications during Photonics West 2025.

-

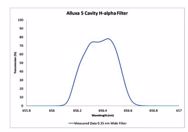

Alluxa, Inc. announces the development of two groundbreaking Hydrogen Alpha (H-alpha) Emission Line Filters for astronomy applications. Alluxa’s novel H-alpha filters are revolutionizing the ultra-narrow optical filters market.

-

Alluxa, Inc., a global leader in high-performance optical coatings and filters and thin-film deposition technologies, announces the expansion of the online product catalog featuring hard-coated specialty filters with extended wavelength ranges from the ultraviolet (UV) to infrared (IR). Alluxa will be showcasing the new catalog optical filters during SPIE Defense + Commercial Sensing at Gaylord Palms Resort & Convention Center, Orlando, FL, April 5 - 7, 2022, in booth #1525.

-

Alluxa, Inc., a global leader in high-performance optical coatings and filters and thin-film deposition technologies, announces the promotion of Amber Czajkowski to the position of Director of Product Management, effective immediately. Ms. Czajkowski will be responsible for applications and product engineering.

-

Alluxa’s proprietary SIRRUS™ Plasma Deposition platform offers breakthrough high performance and full spectral coverage from 200 nm to 14 µm.

-

Alluxa, Inc., a global leader in high-performance optical coatings and filters and thin-film deposition technologies, is pleased to announce the appointment of Jacob Jaramillo to the position of director of sales operations.

-

The company’s unique multi-band optical filter design is integral to Texas A&M’s Exoplanet Transmission Spectroscopy Imager (ETSI) instrument.

-

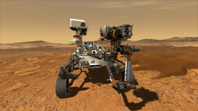

Alluxa’s optical filters, specially designed for the advanced fluorescence spectrometer on the Mars Perseverance Rover, landed safely on Mars, on February 18, 2021.

-

Alluxa, Inc., a global leader in high-performance optical coatings and filters and thin-film deposition technologies, announces an online catalog of fluorescence filters developed for use in COVID-19 testing devices. The ULTRA SERIES – Fluorescence Filter Sets are specifically designed for real-time qPCR (polymerase chain reaction) applications.

-

Alluxa, Inc., the global leader in high-performance optical coatings and filters, has extended its industry-leading Ultra Series to include high-performance polymerase chain reaction (PCR) specific filters. These filters were developed with higher performance optical characteristics and are intended to improve speed and efficiency of real time qPCR testing for the SARS-CoV-2 virus. The new Ultra Series qPCR product family includes real-time, qPCR-specific filters for integration into medical equipment that performs COVID-19 testing of patient samples.

-

Alluxa, Inc., a global leader in high-performance optical coatings and filters and thin-film deposition technologies, introduces a breakthrough 10.6 µm infrared (IR) notch filter with optical density > 4.0 (OD4). The innovative, high-layer-count IR optical coating is produced by utilizing Alluxa’s proprietary deposition capabilities that now deliver groundbreaking optical coating performance in the 8 µm to 12 µm spectral range.

-

Alluxa, Inc., a global leader in thin-film deposition technology and high-performance optical coatings and filters, is pleased to announce Bill Kastanis as the new vice president of operations, effective immediately. A highly-respected veteran in optics and photonics, Bill has over 35 years of experience in operations, vacuum deposition, and factory automation.

-

Alluxa, Inc., a global leader in high-performance optical filters and optical coatings, is pleased to announce the promotion of Kevin Nolen to director of engineering, effective immediately. Kevin has served in a variety of engineering and operations roles at Alluxa for more than 12 years. He will be responsible for guiding and executing Alluxa’s developmental engineering efforts that support factory automation, deposition process improvements, and product engineering projects. Kevin has a BS ME from California State University, Chico.

-

Alluxa’s proprietary SIRRUS™ PVD platform offers breakthrough high performance and full spectral coverage from 200 nm to 14 μm.