Technical Capabilities Required To Ensure Successful Vacuum Window Fabrication

By Kevin Quist, National Sales Manager – Optics, Zygo

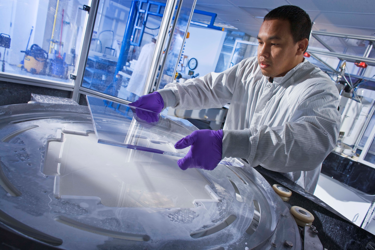

Successful vacuum window fabrication hinges on several advanced technical capabilities. This article delves into the essential aspects, including precision machining, advanced polishing, and state-of-the-art coating techniques that ensure optimal optical performance. Understanding material properties, such as those of fused silica, sapphire, and Zinc Sulfide, is crucial for creating windows that withstand extreme conditions while maintaining high transparency and strength.

Quality control is paramount, employing sophisticated metrology tools to detect even the smallest deviations that could impact performance. The integration of innovative technologies and a deep understanding of material behaviors further enhance the quality and reliability of vacuum windows. Learn how a culture of continuous improvement and extensive industry experience contributes to the successful manufacture of these critical optical components used in high-stakes environments.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Photonics Online? Subscribe today.