Extreme Precision Optics Group

Zygo’s extreme precision optics group provides services involving aspheric surface fabrication, computer controlled optical surfacing, ion beam figuring (IBF), precision glass machining, abrasive machining, and precision glass assembly.

The extreme precision optics group is comprised of over 20 engineers with experience ranging from Hubble Space Telescope repair through developing precision optics for use in lithographic systems. This page provides an overview of the different services this group offers for medical, life science, military, semiconductor, and industrial applications.

from Hubble Space Telescope repair through developing precision optics for use in lithographic systems. This page provides an overview of the different services this group offers for medical, life science, military, semiconductor, and industrial applications.

Aspheric Surface Fabrication - Zygo works with sizes up to 500 mm and uses Zerodur, ULE, glass, ceramics, Si, and CaF2 materials. This fabrication service provides accuracy to λ/5000 RMS @ 633 nm and does so using computer controlled optical surfacing, ion beam figuring, and precision optical and CMM metrology.

Computer Controlled Optical Surfacing - This service can achieve 1 nm RMS surface figure and 0.2nm RMS surface roughness in aspheres, precision spheres, flats, and cylinders through Zygo’s Computer Controlled Optical Surfacing technology.

Ion Beam Figuring – Another proprietary technology, Zygo’s IBF uses an Argon ion stream to “polish” aspherical, spherical, and flat optical surfaces. It can achieve a <0.25 nm surface figure and will not scratch surfaces its applicable to a wide range of materials such as zerodur ule glass ceramics si and caf2 and is particularly well suited for use with surface geometries that aren’t accessible to conventional polishing.

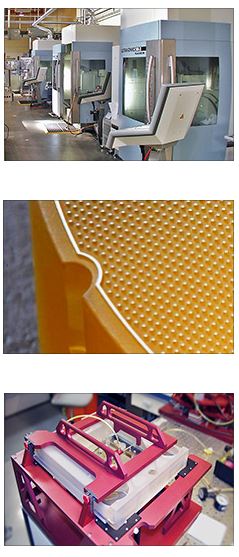

Precision Glass Machining – Zygo’s precision glass machining features 3 and 4 axis  CNC machining, as well as 5-axis ultrasonic CNC machining (3 to 5 times faster than standard CNC machining), and post machine hydrofluoric acid-etching. 5 µm tolerances are typical, though 2µm can be achieved on key features post-acid etch. Machining can be done to sizes up to 750 mm.

CNC machining, as well as 5-axis ultrasonic CNC machining (3 to 5 times faster than standard CNC machining), and post machine hydrofluoric acid-etching. 5 µm tolerances are typical, though 2µm can be achieved on key features post-acid etch. Machining can be done to sizes up to 750 mm.

Abrasive Machining – Masking and machining are the two processes involved in Zygo’s abrasive machining services. This is ideal for fabricating flexible clamp membranes for reticle chucks and for patterning wafer table surfaces.

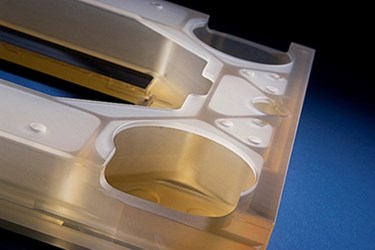

Precision Glass Assembly – Precision glass assembly is conducted in class 10000 and class 100 assembly areas and benefits from Zygo’s proprietary and custom designed tooling. Tolerance to 10 µm position and 1µm parallelism can be achieved in glass to glass and glass to metal bonding.

Contact Zygo to see if they can provide precision optics for your next military/defense, medical, life science, semiconductor, or industrial application.