ZYGO Electro-Optics Group

ZYGO offers integrated system design, prototyping, and volume assembly in product development phases like engineering and product development, electro-optical assembly, opto-mechanical assembly, and turnkey system manufacturing.

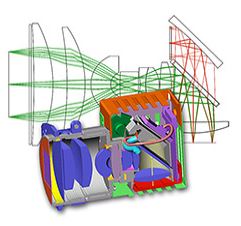

Engineering and Product Development

This phase typically involves developing Scope of Work, building a prototype, redesigning to improve overall performance, quality, and cost, or even taking your current electro-optical system through a design for manufacture and assembly phase. Successful product launches are more likely to occur when Zygo’s Electro-Optics group is included early on in the development cycle. ISO 9001 and ISO 13485 standards, Tier 1 volume optical capabilities, program management capabilities, and more are combined to ensure design goals and capabilities are synchronous with process and manufacturing capabilities, leaving Zygo poised to take on even the most demanding electro-optical system development challenges.

Electro-Optical Assembly

Zygo’s electro-optics group has designed a wide variety of complex electro-optical systems, from objectives used in medical and semiconductor processes that required dynamic focusing, to 3-D imaging devices used in dentistry. Class 100,000 to class 10 clean room assembly areas are available to ensure that assembly take place in the appropriate climate, with parameters in place to control particle, temperature, humidity, and ionization. Additionally, ESD control and laser handing processes are implemented to handle electronic, mechanical, and optical assemblies.

Opto-Mechanical Assembly

Doublets, beam expanders, complex illumination systems, and critical laser delivery systems are just some of the opto-mechanical assemblies that Zygo has helped to design and manufacture in the past. Optical alignment stations coupled with real time optical compensation techniques are utilized to bring lab-like engineering and precision to the production floor. Zygo’s optical mechanical assembly services have been used in the past for coating design, metrology, contact bonding, lens design, and much more.

Turnkey Systems Manufacturing

All of the design and engineering efforts in the world won’t matter if you don’t have a solid manufacturing system in place for your electro-optical assembly. Zygo can manufacture your product in high volume without comprimising quality, performance, and cost parameters. Their production location is ISO 9001, ISO 13485, ITAR, and FDA registered, and also maintains class 100,000 to class 10 clean rooms. Examples of some of the systems Zygo has manufactured successfully in the past include telescopes, ophthalmological surgical systems, molecular imaging systems, diagnostic systems, long range surveillance systems, helmet mount displays, and more.

Contact Zygo to see if their Electro-Optics group can help you with your electro-optical assembly.