Coherence Scanning Interferometry (CSI) Technology

When selecting a 3D optical metrology solution, users should prioritize speed, measurement precision, magnification range, and the ability to measure surfaces from super-smooth to extremely rough.

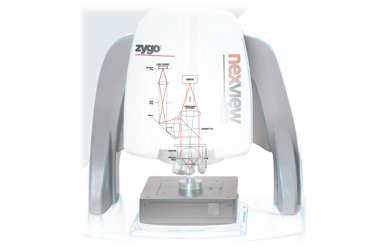

ZYGO's Coherence Scanning Interferometry (CSI) based 3D Optical Profilers deliver best in class performance in all of these categories. These systems use the principle of optical interference to measure a sample.

As shown in the image, illumination is divided into two paths where one travels to a precision reference surface, and the other travels to the test surface. The reflections from these two surfaces combine at a camera detector where they interfere with each other, and a pattern of light and dark intensities is created. That interference pattern represents the surface topography of the test surface.

In ZYGO's systems, interferometer is contained in the microscope objective, which provides both magnification as well as the integrated reference; and a filtered white light source is used to illuminate the surface through the objective. The short coherence length of white light causes the focus depth over which interference occurs to be quite shallow - this enables CSI to examine rough and discontinuous surfaces just as easily as smooth ones.

To create a map of the test surface, the objective or the entire microscope head is moved ('scanned') perpendicular to the sample under test. A high speed, low noise digital camera monitors the interference signal, and the advanced signal processing algorithms in ZYGO's Mx software interpret this signal for each pixel in the field of view in seconds.

CSI presents a number of advantages over other surface measurement technologies:

- It delivers very precise nanometer or sub-nanometer height precision at all magnifications

- It is a fast, consistent measurement, typically producing – 1.9 million pixels in just a few seconds - again, at all magnifications

- CSI can be used on surfaces of virtually any material, color, and surface conditions. It functions just as well whether the sample is super-smooth, very rough, flat, curved, sloped, optically transparent, translucent, or opaque.

- CSI is able to use additional signal processing to measure in the presence of transparent optical films that confound other measurement methods.

These advantages combine to provide exceptional application versatility as the same instrument can be used for a wide range of applications.