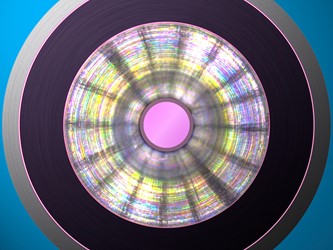

Coating Of Fiber End Faces: Increased Capacity And Quality Thanks To Optimized Technology

Bedford, NH: LASER COMPONENTS USA, specialized provider of components and services in the laser and optoelectronics industry, has been able to significantly expand its range of services for the coating of fiber end faces. The company is now in a position to produce larger quantities and at the same time has created ideal conditions for processing other fiber types. This means that customers benefit from a larger product range and price advantages through cost-efficient production.

“Depending on assembly configuration, we can now process fibers with large bending radii or very large core diameters up to 1000 µm. This opens up additional possibilities, especially in the field of multimode fibers,” explains Florian Tächl, fiber optics specialist at LASER COMPONENTS.

An improved ion source has also improved the surface quality of anti-reflective coatings. Depending on the coating and wavelength, LASER COMPONENTS achieves back reflections from 0.5% to 0.2%. Especially when coupled into active elements, back reflections can impair their function or even damage components.

» Download picture

» Further product information

About LASER COMPONENTS

LASER COMPONENTS specializes in the development, manufacture, and sale of components and services in the laser and optoelectronics industry. At LASER COMPONENTS, we have been serving customers since 1982 with sales branches in five different countries. We have been producing in house since 1986 with production facilities in Germany, Canada, and the United States. In-house production makes up approximately half of our sales revenue. A family-run business, we have more than 220 employees worldwide.

Source: Laser Components