Build It Right Every Time: Ensuring Laser Accuracy In Semiconductor Systems

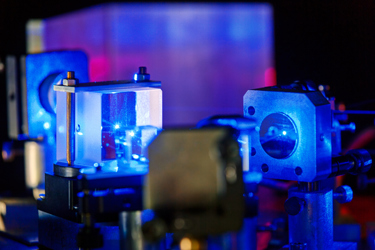

In high-precision fields like semiconductor manufacturing, where lasers are used for processes such as drilling PCBs and dicing wafers, system consistency is paramount. Unnoticed laser drift—caused by source degradation, optical misalignment, or environmental factors (temperature/vibration)—is a "silent killer" that can result in dozens of faulty units and significant yield loss before detection.

To preempt this variability, manufacturers must move beyond reactive quality control. Two primary monitoring strategies are available:

- Spot-Check Monitoring: Periodically measuring laser output between production batches. Simple, but introduces a delay in problem detection.

- In-Line Monitoring: Continuously diverting a fraction of the beam for real-time measurement, which is more complex but prevents bad parts from being produced entirely.

The content stresses that laser monitoring must be built into the system from day one. Integrating measurement solutions early provides better control over performance and simplifies system architecture. Products like Gentec-EO’s INTEGRA series combine a detector and meter into a single compact unit, offering full visibility of the laser's output and enabling full automation via serial commands.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Photonics Online? Subscribe today.