World's Thinnest Hologram Integrates With Smartphones And Wearables

By Jof Enriquez,

Follow me on Twitter @jofenriq

Researchers at Royal Melbourne Institute of Technology (RMIT), working in collaboration with counterparts at Beijing Institute of Technology (BIT), have developed the world's thinnest nanometric hologram, making it possible for the first time to integrate 3D holography with smartphones and wearable devices.

Conventional holograms modulate the phase of light based on the propagating distance in 3D bulky materials, which requires the thickness of holograms within optical wavelength ranges. This limits their integration with thin electronic devices.

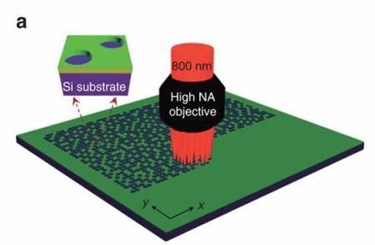

RMIT and BIT researchers, however, have been able to overcome this limit and successfully created 60 nm holograms using a topological insulator material.

Through their research published in Nature Communications, they found out that "nanometric topological insulator thin films act as an intrinsic optical resonant cavity due to the unequal refractive indices in their metallic surfaces and bulk. The resonant cavity leads to enhancement of phase shifts and thus the holographic imaging."

Until this achievement, holograms have proven impractical to fit atop mobile devices. But RMIT University’s Distinguished Professor Min Gu, who led the project, says "Our nano-hologram is also fabricated using a simple and fast direct laser writing system, which makes our design suitable for large-scale uses and mass manufacture."

Zengji Yue, a research fellow at RMIT University and co-author of the research paper, described to IEEE Spectrum the 3D printing method: "A femtosecond laser manages to ablate the thin film material on a substrate quickly, producing centimeter-scale holograms for practical applications."

There are myriad applications for such hologram technology in optical imaging, data storage, and information security, across multiple industries. But arguably the most obvious one is integration with consumer electronic devices.

"Integrating holography into everyday electronics would make screen size irrelevant – a pop-up 3D hologram can display a wealth of data that doesn’t neatly fit on a phone or watch," Gu said in a press release.

"From medical diagnostics to education, data storage, defense, and cybersecurity, 3D holography has the potential to transform a range of industries and this research brings that revolution one critical step closer," he added.

It may take some time and effort to overcome further engineering hurdles before the potential can be realized, though. The researchers say they will have to shrink their hologram ten times smaller, and create a suitable rigid thin film coating for surfaces of mobile devices to enable the projection of 3D holographic images. Making a flexible version of the film will open up even more possibilities.