World's First Flat Lens Focusing On Continual Bandwidth Of Colors

By Jof Enriquez,

Follow me on Twitter @jofenriq

Harvard engineers have built the first achromatic metalens (AML) that operates over a continual bandwidth of colors, from blue to green, through a technique called dispersion engineering and via an ultra thin array of nanopillars.

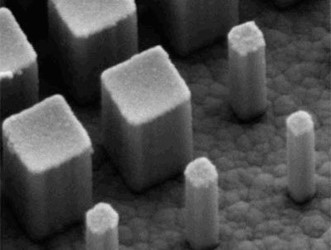

Researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) last year demonstrated the first planar lens that works with high efficiency within the visible spectrum of light. The flat lens consists of titanium dioxide nanopillars on a glass substrate, which focuses light to a spot smaller than the wavelength. This unique structure enhances image resolution far sharper than state-of-the-art commercial lenses.

The planar lens was named a runner-up for Science's Breakthrough of the Year 2016 by the journals Nature and Science. It had one significant drawback, though, because it could only focus one color at a time. A phenomenon called chromatic dispersion causes different colors with different wavelengths to bend at a variety of angles by a flat lens.

Now, the researchers at SEAS have returned to the lab to correct chromatic dispersion in their award-winning flat lens so that it can work within a continual bandwidth of colors, from blue to green, akin to an LED. They optimized the shape, width, distance, and height of the nanopillars to focus different wavelengths, from blue to green, thereby controlling light through unconventional means.

"This is accomplished via dispersion engineering of dielectric phase shifters: titanium dioxide nanopillars tiled on a dielectric spacer layer above a metallic mirror. The AML works in reflection mode with a focal length independent of wavelength from λ = 490 to 550 nm. We also design a metalens with reverse chromatic dispersion, where the focal length increases as the wavelength increases, contrary to conventional diffractive lenses," the researchers explain in a paper published in Nano Letters.

“Traditional lenses for microscopes and cameras — including those in cell phones and laptops — require multiple curved lenses to correct chromatic aberrations, which adds weight, thickness and complexity,” said Federico Capasso, Robert L. Wallace Professor of Applied Physics and Vinton Hayes Senior Research Fellow in Electrical Engineering, in a news release.

Harvard's flat lens can be tailored to a wide range of applications, including imaging under LED illumination, fluorescence, and photoluminescence spectroscopy, as well as for camera modules for cell phones and laptops, wearable optics for virtual reality and augmented reality, flexible contact lenses, or telescopes in space.

The researchers claim that the technology is easily compatible with conventional integrated circuit mass production and up-and-coming fabrication techniques.

“This method for dispersion engineering can be used to design various ultrathin components with a desired performance,” added Zhujun Shi, a PhD student in the Capasso Lab and co-first author of the paper. “This platform is based on single step lithography and is compatible with high throughput manufacturing technique such as nano-imprinting.”

The Harvard SEAS research team now is exploring commercialization options for their breakthrough flat lens technology.