Vision system inspects liquid crystal displays (LCD)

By: Doug Wilson, Engineering Technology Center

Automated testing and inspection of the LCDs and LEDs commonly found on pagers, cellular phones, and medical instruments needs to be accurate, detailed, and fast. Even subjecting an LCD display to traditional electronic functional testing using automated test techniques does not guarantee that the proper pixels and characters are being displayed, because voltage and current readings do not correlate perfectly with pixel display states.

The best method for verifying display performance is inspection. Human inspection of high-resolution LCDs can be tedious and error prone. With the increased speed of PC hardware, a PC-based optical inspection system can acquire and process images with sufficient speed and accuracy to be a far superior approach to other inspection methods. The Engineering Technology Center (ETC) of Mystic, CT, has designed a PC-based automated optical inspection system for conducting functional testing of LCD and LED panels.

Testing Requirements

Dot matrix LCDs, as well as seven-segment LCDs and LEDs have certain characteristics that must be tested.

Pixel and character spacing tests are needed to ensure that each pixel is situated properly Pixel functionality tests are needed to check that each pixel can be switched on and off Character recognition testing is required to test the electronics controlling the pixel switches because faulty circuits can produce incorrect pixel combinations for a particular character Contrast testing is needed to ensure that the display has the proper brightness

Dot matrix LCDs are generally more difficult to test than seven-segment displays because failures are more difficult to detect. Precise image sampling is required because pixels are more numerous and are much smaller than the segments. The placement and orientation of the LCDs can vary from part to part, creating a problem of locating the pixels within an acquired image.

Therefore, the imaging analysis algorithms must be capable of locating the characters within a range of orientations. In addition, the display is often covered by a protective film that can create a glare and/or become dirty during the assembly process. This condition creates distorting artifacts in the image that need to be distinguished from the actual display.

The ETC LCD Inspection System is capable of performing all of the tests required for maintaining high standards of quality control. The system is also versatile, accommodating any dot matrix arrangement as well as seven-segment displays and LEDs. The display can be tested and automatically accepted or rejected based on tolerances for the characteristics under test.

Software

Before a display can be tested, the LCD characters must be found within the image. This is accomplished with a robust positioning algorithm that compensates for angles of rotation varying from one unit to another as well as XY translation and scale. The positions are determined to subpixel accuracy using IMAQ Vision edge-detection tools with quadratic interpolation. This algorithm ensures an accurate definition of sampling coordinates regardless of image magnification or variations in the placement of the unit under the camera.

The ETC software employs IMAQ Vision filtering functions and background normalization to eliminate glare and other distorting artifacts in the images acquired so we can test through the protective film covering LCDs. The software filtering also reduces misdetections and improves overall accuracy.

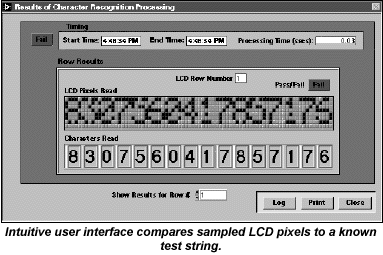

Once the image is filtered and the pixel positions located, the image is sampled to determine each pixel value. Several tests can be performed with this data. A pixel functionality test can be done to determine if all the pixels are working, and at the same time,to check for proper pixel spacing. An optical character recognition determines the specific characters displayed from the image for comparison with a known test string. The contrast of the display can also be measured from the image to determine if it is within the specified tolerance.

In addition to image acquisition and processing, the software is capable of incorporating motion control into the test sequence. A dual-axis motion control stage or a single stepper/servo motor can move the LCD units through the cameras field of view for testing. In this configuration, the entire test system is integrated into a single PC.

Another useful feature of the system is the image database. The images from failed tests can be stored in the database so they can be viewed at a later time to help determine the source of the production errors. The image database can also be used to verify that the system is calibrated and operating properly.

Hardware

The National Instruments IMAQ PCI-1408 image acquisition board speeds up image processing by performing several functions in hardware, such as image scaling, decimation, binary image thresholding, and gamma correction. This capability greatly reduces the computational load on the CPU to provide quicker image processing.

The ETC LCD Testing System is a high-speed, accurate, and versatile solution to the many challenges of display testing. The LCD Testing System can perform several different tests on dot-matrix LCDs and seven-segment LCDs and LEDs. It also has integrated motion control capabilities, so that you can perform all display tests on a single system. The result is not only saving production space and time, but also standardizing test reports and unifying all of the testing under one user interface.

About the author…

Doug Wilson is with the Engineering Technology Center, 240 Oral School Road, Mystic, CT 06355-1208, tel (860) 572-9600, fax (860) 572-7328.