The Latest And Greatest Optical Component Innovations

By John Oncea, Editor

Optical components date back thousands of years, with lenses evolving from ancient to modern innovations, shaping fields like medicine, aerospace, and AI.

The history of optical components spans thousands of years, with significant developments occurring from ancient times to the modern era. Egyptians and Mesopotamians developed early versions of lenses as far back as 2000 BCE, and some claim Chinese astronomers were using rock crystals of topaz to observe the stars 300 years earlier.

But the earliest known lenses we know of can be traced to an ancient Semitic kingdom and sometimes empire that existed as an independent state from around 2500 BCE to 605 BCE, spanning the Early Bronze Age through to the late Iron Age.

Introducing … The Assyrians

At its peak, the Assyrian Empire stretched from Cyprus in the Mediterranean Sea to Persia, and from the Caucasus Mountains (Armenia, Georgia, Azerbaijan) to the Arabian Peninsula and Egypt. Some 3,000 years ago, during the final stage of the Assyrian Empire, the Assyrian people were building on the foundation created by the Sumerians to advance medicine and establishing schools throughout the Empire (albeit only for the sons of the wealthy and nobility).

Like all Empires, the Assyrians saw good times and bad, periods of growth and decline, and leaders who thrived and others who failed. The Empire remained powerful for hundreds of years until the 600s BCE when it fell apart.

The decline and fall of the Assyrian Empire were pretty standard, as far as declines and falls go. According to World History, the Empire had grown too large, the regions were overtaxed, and the vastness of its domain made it difficult to defend the borders. In 612 BCE a coalition of Babylonians, Persians, Medes, and Scythians attacked and burned several Assyrian cities so effectively that, within two generations of the Empire’s fall, no one knew where the cities had been.

The Assyrian Empire is remembered today for its formidable military prowess, skilled cavalry, and brutal tactics used to conquer vast territories, often leaving a reputation for cruelty and detailed records of their conquests through written accounts. Essentially, they were known for their exceptional military might and efficient systems of governance across a large Empire.

The Assyrians were also known for technological advancements such as building roads and their skill at ironworking. “They were the first in the area to develop iron weapons, which were superior to the bronze weapons their enemies were using,” writes National Geographic. “Their skill at ironworking allowed them to make weapons and protective items more cheaply, so more soldiers could use them.

“In addition, they were the first army to have a separate engineering unit, which would set up ladders and ramps, fill in moats, and dig tunnels to help the soldiers get into a walled city. They were also among the first to build chariots, which provided greater protection on the battlefield. These technological advancements allowed the Assyrians to go on the offensive and attack neighboring areas for the first time, which led to the expansion of their empire.”

Not all of the advances made by the Assyrians were militaristic. Around 750 BCE – while under the rule of Tiglath Pileser III – they were conducting extensive reforms of the army, reasserting central control over the Empire, reconquering the Mediterranean seaboard, and even subjugating Babylon.

Well, okay, that’s all militaristic. But around the same time, Assyrian craftsmen were grinding quartz or rock crystals that some opticians believe were intentionally being made into magnifying lenses. Others suggest the lenses were being made to be used to start fires or for decorative inlay for furniture.

The lens most commonly associated with the Assyrian Empire is called the Nimrud Lens which was discovered in the ruins of the Assyrian palace at Nimrud, modern-day Iraq in 1850 by archaeologist Austen Henry Layard. According to IFLScience, “Professor Giovanni Pettinato of the University of Rome claimed in 1999 that the lens could explain the ancient Assyrians’ knowledge of astronomy. Pettinato added that ancient Assyrians depicted Saturn as a god surrounded by serpents, suggesting that they could have seen Saturn’s rings.”

But alas. The curator of The British Museum, at which it is displayed, wrote of it, “There is no evidence that the Assyrians used lenses, either for magnification or for making fire, and it is much more likely that this is a piece of inlay, perhaps for furniture.”

Still, it could be argued that the Nimrud Lens might have been the first optical component ever invented, even if the craftsmen making them didn’t know it at the time.

425 Years In 261 Words

While we can quibble over when the manufacturing of optical components began, it’s safe to say that modern optics manufacturing began in the early 17th century, when the spectacle-maker Hans Lipperhey patented his famous telescope.

Oh, sure. Wearable eyeglasses were invented in the 13th century and spectacle makers in Venice, Florence, the Netherlands, and Germany improved lens grinding and polishing techniques throughout the Middle Ages and Renaissance.

But, according to the National Center for Biotechnology Information, “It is said that to improve the imaging quality of telescopes, Galileo Galilei acquired contemporary lens-making skills (in the early 1600s). Optics manufacturing was purely manual work until the invention of the first grinding machines by Joseph von Fraunhofer and Johann Heinrich August Dunker, at the beginning of the 19th century.”

The evolution of optical glass production and manufacturing has been marked by significant milestones since then. In the late 19th century, the collaboration between Carl Zeiss, Ernst Abbe, and Otto Schott revolutionized the industry by enabling large-scale production of optical glasses with well-defined properties. The 1980s and 1990s saw further advancements with computer-aided approaches and standardized polishing processes, opening new possibilities for mass-market optics.

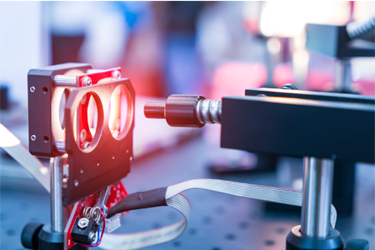

Today, the demand for high-quality optical components continues to drive innovation. Manufacturers are developing novel techniques to meet the stringent requirements of UV optics and high-power laser devices. Polishing has reached atomic-scale precision, and new methods are being explored for aspherization and freeform optics production. Reducing surface damage and contamination also has become a critical focus.

While traditional methods still have their place, the field has expanded to include innovative techniques such as magneto-rheological finishing, plasma etching, ion beam etching, fluid jet polishing, and laser-based structuring. These advancements demonstrate that despite its ancient roots, optics manufacturing continues to evolve, adapting to meet future challenges and demands.

Modern Optics Manufacturing

Recent innovations in the manufacturing of optical components include coatings engineered at the nanoscale level that control light absorption, reflection, and spectral selectivity, enabling applications like high-efficiency solar cells and anti-reflective coatings. There are also advanced lens materials, developed with superior optical properties for improved image quality and performance in various environments.

Don’t forget micro-optics for miniaturization, the design and manufacturing of optical components on a microscopic scale, allowing for smaller, more compact optical systems, as well as the utilization of 3D printing techniques to fabricate complex optical components with greater design flexibility and high-precision molding of glass to create complex lens shapes with an excellent surface finish for mass production.

But, as is usually the case, there’s more. Take high-speed optical interconnects, for example. According to Lightwave Online, the demand for higher bandwidth in AI and data center applications is driving rapid advancements in optical interconnect technologies. 800G coherent pluggable optics based on 5-nm digital signal processor (DSP) technology are now commercially available and the industry is already working toward 1.6 Tbps and 3.2 Tbps optical components to meet future bandwidth demands.

The exponential growth of artificial intelligence (AI) applications is accelerating the development of optical components, as well. By 2025, the majority of ports in AI networks are expected to be 800 Gbps, and by 2027, 1600 Gbps leading to the development of 100G SERDES, linear drive optics, and co-packaged optics to handle the throughput required by AI/ML applications while maintaining power efficiency.

Addressing power consumption concerns is a major focus, too. Coherent pluggable optics are gaining attention for their improved power efficiency, helping to drive down energy costs while improving performance and capacity. At the same time. The industry is exploring various solutions to reduce power consumption, which is becoming a significant issue as speeds increase.

Lightwave Online further notes there’s a growing trend toward open and interoperable optical networking solutions with many carriers accelerating their adoption of open optical networking to overcome economic challenges and improve network flexibility. This shift allows for mixing and matching components, preventing vendor lock-in, and making networks more resilient to supply chain disruptions.

Finally, several innovative technologies are beginning to emerge. Co-packaged optics (CPOs) are in development and may become crucial for enabling higher speeds in the future. In addition, the use of materials like indium phosphide and silicon nitride is being explored for optical computing and data communication.

The Current State Of Optical Component Manufacturing

Today, the field of optics continues to evolve with ongoing research into areas such as nanophotonics, quantum optics, and adaptive optics. And, when all is said and done, these new and improved optical components with be applied in numerous ways, including:

- Medical Imaging: Enhanced endoscopes and robotic surgical imaging systems with improved clarity and precision.

- Life Sciences: Advanced optical microscopy techniques for detailed biological analysis.

- Aerospace and Defense: High-performance optical systems for advanced weaponry and satellite imaging.

- Industrial Applications: Optical sensors for precise quality control and inspection.

The history of optical components demonstrates the continuous progression from simple lenses to highly sophisticated optical systems, driven by advances in both scientific understanding and manufacturing capabilities.

And to think it (maybe?) started with the Assyrians.