The Evolution Of Metrology: From Cubits To Augmented Reality

By John Oncea, Editor

Metrology evolved from ancient Egyptian cubits to the metric system, driving scientific progress. Modern trends include AI, automation, and nanoscale measurements for sustainability.

About this time last year, we took a look at who is shaping the direction of metrology. Let’s go ahead and take a look at what, exactly, the direction metrology is taking looks like.

But first, what is metrology?

Umm, What Is Metrology?

Good question. Fortunately, our friends at Zygo Corporation can get us started toward understanding the science. “Today we recognize metrology as the science of measurement. While it may seem as though it is a recent concept, applicable to the increasingly more complicated products manufactured worldwide, its beginnings stretch far back in history.”

The history of metrology dates back to the beginning of the Bronze Age, the invention of writing, and the establishment of the kingdom of Egypt where “an Egyptian pharaoh realized that there had to be some standard by which to measure length (because) without a measurement standard, the pyramids could not have been built.

“What followed was the Royal Egyptian Cubit, which was made out of granite. Even then the pharaoh decreed that the subsequent wooden cubit devices be routinely compared to the original granite standard, and thus calibration of the measurement instrument began.”

The cubit and numerous other attempts at standardizing measurement over the next several thousand years fell by the wayside due to problems with quality and consistency. Then, in 1795, the French Revolution began and, with it, the creation of the metric system.

The metric system “simplified a great many calculations, including the need to divide by 16 to convert pounds to ounces, or by 12 to convert feet to inches,” writes Zygo. “The Commission working on the metric system called the unit of length “the meter.” Other units of measurement followed.”

More countries adopted the metric system between 1795 and 1875 and, to ensure international conformity, the International Bureau of Weights and Measures was formed by the Metre Convention on May 20, 1875. Although the original mission of the IBWM was to create international standards for units of measurement and relate them to national standards to ensure conformity, its scope has broadened to include electrical and photometric units and ionizing radiation measurement standards.

“By 1901, the United States government acknowledged that measurement standards were not just a priority, but a necessity for commerce, trade, and science to grow and advance,” Zygo writes. “Congress acted, and a law creating the National Bureau of Standards was passed. It is currently known as the National Institute of Standards and Technology or NIST (and it) makes management of a complex set of measurement standards possible.”

Over the past 120 years, technology has made remarkable advancements, largely thanks to the critical role of metrology industries such as engineering, aerospace, manufacturing, consumer electronics, energy, healthcare, automotive, and defense – all of which rely on precise measurement to ensure the quality, speed, and consistency of their products.

What do the next 120 years hold in store for metrology? Honestly, we have no idea. But we can take a look at what the next decade or so might look like.

Metrology Continues To Evolve

“Metrology,” according to World Metrology Day, “provides the foundation for data-driven decision-making and policy development in sustainability. By ensuring accurate measurements across various aspects of sustainability, it helps organizations, governments, and individuals make informed choices that contribute to a more sustainable future.”

It also continues to evolve several trends emerging, trends that are making metrology more precise, efficient, and aligned with modern technological and environmental demands. Amongst those trends is a trio of technologies that are often lumped together: automation, artificial technology (AI), and machine learning.

Automation is streamlining complex measurement tasks, reducing human error, and increasing efficiency, writes Verus Metrology Partners. AI and machine learning algorithms are being integrated into metrology systems to enhance data analysis, pattern recognition, and decision-making for improved quality control.

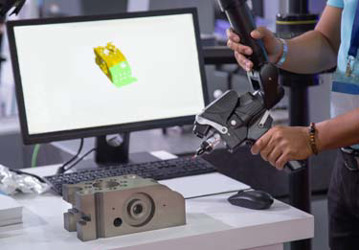

And don’t forget augmented reality (AR) which is being used in metrology applications and allows technicians to overlay digital information onto physical objects during the measurement process, improving accuracy and efficiency.

Next, there’s a growing focus on developing smaller, more portable devices that can be used in the field, or metrology at the nanoscale level. The development of highly sensitive diagnostic tools and miniature medical devices is helping bring metrology out of the lab and into real-world scenarios.

Then there’s the continued development and integration of advanced imaging technologies, such as high-resolution 3D imaging and multispectral imaging, for improved diagnostics and visualization, particularly in medical devices.

All of these trends are helping integrate metrology with Industry 4.0 technologies including digital twins and the Internet of Things (IoT), notes Nordic Metrology. This relationship allows for real-time monitoring, analysis, and optimization of manufacturing processes due to seamless connectivity, data sharing, and remote monitoring.

The ultimate benefit, however, is that metrology is now playing a crucial role in promoting sustainability with a focus on reducing waste and improving the efficiency of resource use in manufacturing processes.

Connecting A Complex World

Metrology’s journey from ancient Egyptian cubits to today’s advanced measurement systems reflects humanity’s quest for precision and standardization. The field has been instrumental in scientific and technological advancements, shaping industries and enabling global trade.

As we look to the future, metrology continues to evolve with emerging technologies like AI, automation, and nanoscale measurements. These innovations not only enhance accuracy and efficiency but also play a crucial role in promoting sustainability across various sectors. The ongoing development of metrology underscores its enduring importance in our increasingly complex and interconnected world.