SMART Photonics Announces Its Highly-Improved Indium Phosphide PDK Qualified For Use With An Integrated VPIphotonics - PhoeniX Software Design Flow

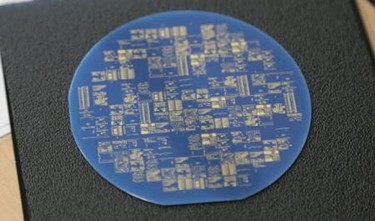

Eindhoven, Netherlands (PRWEB) - SMART Photonics, the world’s first pure-play Indium Phosphide (InP) semiconductor foundry, announced today the availability of an advanced InP process design kit (PDK) for photonic integrated circuit (PIC) design. The SMART PDK has been developed for use in a PIC design flow comprised of software tools from VPIphotonics of Berlin, Germany and PhoeniX Software of Enschede, The Netherlands.

“We are especially pleased by the collaborative work done by our partners, VPIphotonics and PhoeniX Software, to pull together a comprehensive PIC design flow for our InP technology,” said Luc Augustin, CTO at SMART Photonics. “This improved and updated PDK combined with the VPIphotonics – PhoeniX Software design flow will, for the first time, enable PIC designers around the world to use a Schematic Driven Layout flow for a pure-play InP PIC foundry.”

The new PDK is a complete PDK that includes parameterized compact models for use in VPIphotonics’ circuit simulator, VPIcomponentMaker Photonic Circuits. The design flow enables designers to functionally capture their PIC design using a comprehensive library of parameterized photonic building blocks targeted at SMART Photonics’ InP process. The VPIcomponentMaker Photonic Circuits tool provides a scalable time-and-frequency-domain simulation framework for fast and accurate modeling of large-scale PIC designs. Its integrated simulator directly uses the compact photonic models from the SMART PDK to enable simulation of a mix of photonic, electrical and optoelectronic devices.

“This is an exciting time for integrated photonic design,” said André Richter, General Manager of VPIphotonics. “The combination of the SMART Photonics PDK and our VPIcomponentMaker Photonic Circuits software increases designer productivity by enabling them to sweep and optimize layout-defining parameters while transparently supporting fabrication-based sensitivity and yield analysis for optimal design performance.”

Orientations and connections of the circuit building blocks can be specified in VPIcomponentMaker Photonic Circuits and then passed to OptoDesigner, PhoeniX Software’s parameterized photonic design tool. OptoDesigner uses foundry fabrication data, parameterized photonic building-blocks and an extensive set of design rules from the SMART PDK, to synthesize a SMART foundry-compatible layout that meets SMART design rules and the designer’s intent as specified during VPI circuit simulations.

“At PhoeniX Software, we have from the very beginning believed in a building-block PDK-based design paradigm to improve designer productivity,” said Twan Korthorst, CEO of PhoeniX Software. “We are especially excited about the release of this improved SMART InP PDK as it directly makes use of the curvilinear design-rule checking features found in our latest 5.1 OptoDesigner release. We believe our work with SMART Photonics and VPIphotonics will provide designers with higher productivity and shorter times from design concept to a working InP PIC design.”

The SMART InP PDK is targeted for SP21 (SMART Photonics Multi-Project Wafer run #21) slated for June 1st 2017, Software from VPIphotonics and PhoeniX Software is available now. The SMART PDK has been qualified with version 9.8 of VPIcomponentMaker Photonic Circuits and the newest release of OptoDesigner, version 5.1.

About SMART Photonics

SMART Photonics is a European based manufacturer of InP Photonics components with production and research facilities located in Eindhoven, The Netherlands. Integrity is key in the services SMART Photonics offers. As an independent Pure Play InP Foundry, we work at the sole discretion of our customers and their businesses.

Teams of highly experienced experts support all of our clients’ requests. Our production services range from epitaxial growth and regrowth to coating and testing of the individual chips. We accommodate both proof-of-concept and volume manufacturing.

Our generic integration process is specifically designed to provide short turn-around time and low-cost prototyping and volume manufacturing for photonic integrated circuits. For further information, please visit us at http://www.smartphotonics.nl.

About VPIphotonics

VPIphotonics sets the industry standard for end-to-end photonic design automation comprising design, analysis and optimization of components, systems and networks. We provide professional simulation software addressing demands in integrated photonics and fiber optics, optical transmission links and networks. Our team of experts performs design services addressing customer-specific requirements, and delivers training courses on adequate modeling techniques and advanced software capabilities. Our award-winning off-the-shelf and customized solutions are used extensively in research and development, and by product design and marketing teams at hundreds of corporations worldwide. Over 160 academic institutions joined our University Program enabling students, educators and researchers an easy access to VPIphotonics’ latest modeling and design innovations. For further information, please visit us at http://www.VPIphotonics.com.

About PhoeniX Software

Pioneering photonics design automation already since 1991, today PhoeniX Software has a global presence and is a trusted and well recognized partner for a large number of organizations. PhoeniX Software enables the easy and cost-effective realization of integrated photonics chips and systems, by means of internally developed superior products and services. Customers range from large OEM’s to start-ups and include some of the world’s top universities and research institutes. As the leader in Photonic IC design solutions, PhoeniX Software will continue to support the transition of PIC technology from the lab into the fab, by anticipating market demand and customer needs. In combination with strategic partners, this results in offering world class design flows and access to all relevant fabrication technologies for our customers. For further information, please visit us at http://www.phoenixbv.com.

Source: PRWeb

View original release here: http://www.prweb.com/releases/2017/03/prweb14163475.htm