Performance Of Large Motorized Rotary Air Bearing Stages For Synchrotron Crystallography

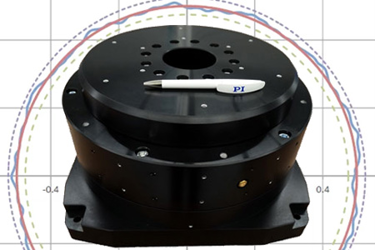

Air bearing rotary tables are often used in beamline and high precision optical applications. PI’s air bearing group recently built a large 300mm diameter rotary table with air bearings for use in a synchrotron beamline test facility for Macromolecular Crystallography.

This stage was designed with the goal of achieving best-possible performance for the following specifications:

- Stiffness

- Load capacity

- Radial runout error motion

- Velocity smoothness

The application required very high tilt stiffness due to a shifting center of gravity in the payload; therefore a large bearing size was selected. The moving mass is less than 5kg and the tilt error motion had to be less than 0.33 µrad. The required tilt stiffness was therefore at least 9 Nm/µrad.

The stage was designed with a slotless brushless direct drive servo motor. Slotless motors offer very low cogging forces, enabling smooth velocity and low error motions. Since this application did not need high speed or acceleration, a slotless motor was an optimal design choice.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Photonics Online? Subscribe today.