Optical Surfaces Aspheric Lenses And Mirrors

Using proprietary production techniques, Optical Surfaces Ltd is a supplier of aspheric parabolic mirrors with off-axis angles approaching 30° and focal lengths as short as 100 millimetres (mm). In addition, benefiting from a stable manufacturing environment, they are routinely able to produce highly aspheric, fast focusing (to f0.7) on-axis parabolic mirrors, according to the company. (An “aspheric” lens or “asphere” is a lens whose surface profiles are not portions of a sphere or cylinder. Per Wikipedia.)

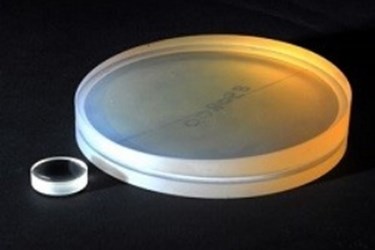

With its team of skilled technicians and engineers, Optical Surfaces can also fabricate high performance aspheric lenses with tight tolerances, per the company. Performance is assured through production of aspheric lenses with surface quality that has low surface scatter (20-10 scratch-dig) and high surface accuracy (lambda/20), according to the company.

The requirement for aspheric mirrors and lenses is particularly prevalent in space-borne optical systems, astronomical telescopes and the next generation of high power laser systems. Driven by the high cost of launching payloads into space, considerable demands are placed upon reducing the size and weight of optical systems. Many of the designs for the new generation of astronomical telescopes use a segmented spherical primary mirror coupled with highly aspheric mirrors in order to compensate for the primary spherical aberration. To achieve the highest laser power densities, fusion researchers require high optical throughput combined with pinpoint-focusing capabilities. The realisation of these optics due to the required large aspherisation is a technical challenge for optical manufacturing.

The complex surface profile of aspheres offers correction of spherical aberration and reduces other optical aberrations when compared to a simple lens or mirror, according to the company. A single aspheric lens or mirror can often replace a more complex multi-element system. The resulting device is smaller, lighter and sometimes cheaper than the multi-element design. On-axis parabolic mirrors produce collimated reflected light and are used in applications that require fast focusing and high energy densities. Off-axis parabolic mirrors provide an unobstructed aperture allowing complete access to the focal region, as well as reducing the size and minimising the weight of a design. They are suitable for broadband or multiple wavelength applications due to their achromatic performance, according to the company.

Optical Surfaces ISO 9001-2000 approved manufacturing facility provides the resources to supply from single specialist requirements to OEM quantities. Benefiting from its stable environment, quality testing becomes quantifiable and reliable. All toroidal (i.e., doughnut-shaped) mirrors are provided with a complete quality test assurance report, according to the company.

Source: Optical Surfaces Ltd