Novel Fabrication Technique To Create Hybrid Silicon Lasers For Mass-Produced Photonic Devices

By Jof Enriquez,

Follow me on Twitter @jofenriq

Researchers at the Agency for Science, Technology and Research (A*STAR) in Singapore have developed a new technique to fabricate hybrid silicon lasers that is considered more economical than current standard manufacturing methods.

Hybrid silicon lasers have long been touted by engineers for their potential to pave the way to low-cost and mass-produced optical devices that can integrate with photonic and microelectronic elements on a single silicon chip for a wide gamut of applications.

Typically, these lasers go through a tedious and complicated process wherein the lasers are fabricated on separate III–V semiconductor wafers before being individually aligned to each silicon device.

“It’s very challenging to etch the entire cavity,” said Doris Keh-Ting Ng, researcher at the A*STAR Data Storage Institute. “Currently, there is no single etch recipe and mask that allows the whole microcavity to be etched, and so we decided to develop a new approach.”

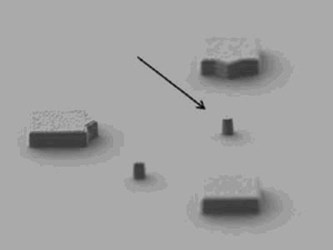

In order to produce a hybrid III–V semiconductor and silicon-on-insulator (SOI) optical microcavity, the researchers used ultrathin interlayer bonding and dual hard mask techniques.

“The heterocore microcavity is realized via ultrathin silicon dioxide interlayer bonding of III–V on SOI and dual hard mask technique. The dual hard mask technique utilizes flowable oxide and silicon nitride as etch masks for III–V and SOI etchings, respectively, and hence, a single lithography is required in the fabrication,” the researchers wrote in ACS Photonics.

Ng said that the new fabrication technique for compact optical-pumped heterocore microdisk lasers “cuts down the number of fabrication steps, reduces the use of hazardous chemicals, and requires only one lithography step to complete the process.”

“The process not only makes it possible to produce heterocore devices, it also greatly reduces the challenges of fabricating them, and could serve as an alternative hybrid microcavity for use by the research community,” added Ng.

The research on hybrid silicon lasers are some of the latest work by A*STAR researchers in the fields of electronics and photonics. Recently, they unveiled a new simulation model that enables the simultaneous electrical-optical interaction inside an optical modulator. The new method could facilitate the development of low-loss, high-speed optical data transmission systems.