NIL Technology Founder & CEO Theodor Nielsen Discusses Flat Optics For AR/VR

By Abby Proch, former editor

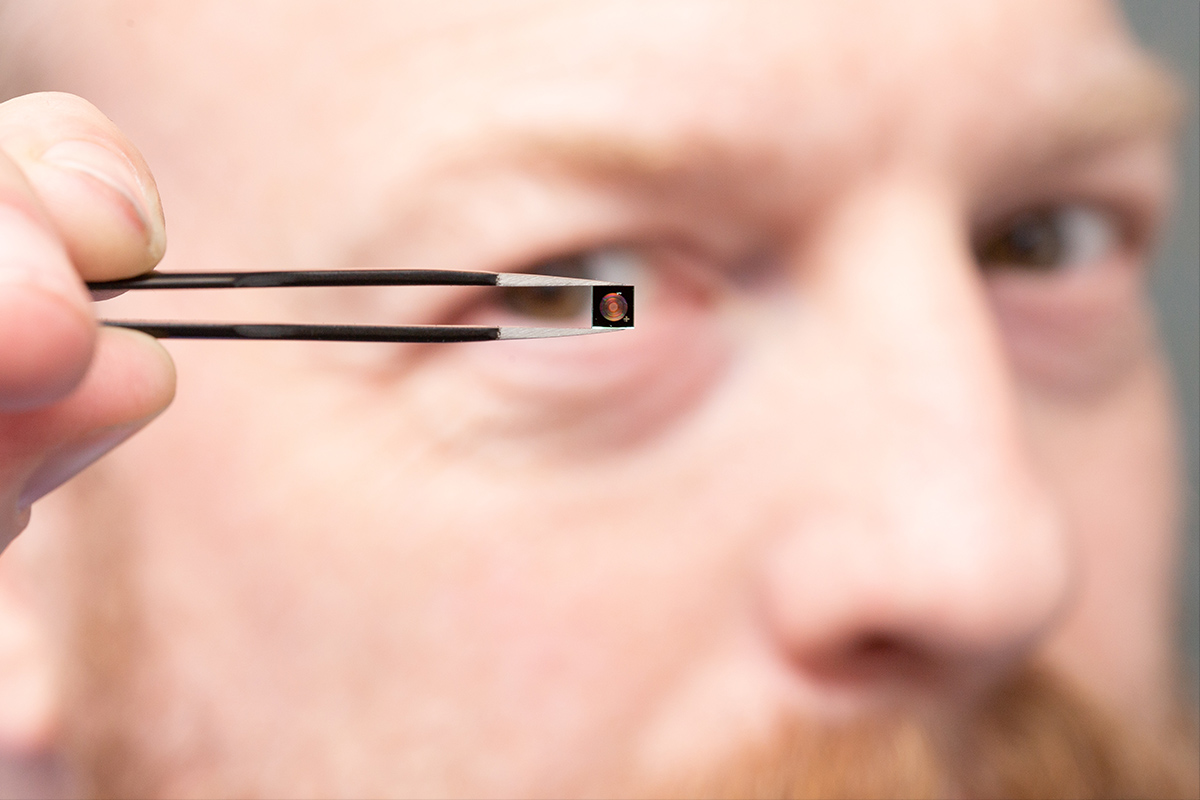

NIL TechnologyFounder and CEO Theodor Nielson explores the groundbreaking improvements in size, weight, and power reduction (SWaP) when using flap optics, or meta optics, in AR/VR applications.

What is “flat optics,” and how does the NILT flat optics platform perform compared with existing optical platforms for AR/VR?

Flat optics, or meta optics, will be a game-changer for optical applications in smartphones, consumer products, and AR/VR/MR devices, to name a few industries. The term “flat optics” comes from the fact that optics can be created by a nanostructured flat surface instead of a traditional curved surface that we are all so familiar with. Optics by nanostructures, or nano-optics, is a diffractive technology while traditional curved optics is refractive. Put in more simple layman's terms, in diffractive optics, the performance of a lens is determined by the wave properties of the light and how the light interferes with itself after passing through a lens, while refractive optics is using the ray properties of light which in its most simple analogy is what happens when things cast a shadow.

What makes nano-optics so interesting is that a lens performance can be engineered using nano-scale precision. This technology has been developed and refined for decades in the semiconductor industry. In nano-optics, the performance of a single lens is not limited by the precision and complex shape of a curved surface, as is the case in refractive optics.

This gives two immediate advantages. 1) More “functionality can be put into a single lens, and therefore fewer lenses are needed to create the desired outcome, and 2) the lenses making up the optical system are all flat, which leads to more simple design rules and reduced size. Also, here semiconductor-related technologies, e.g., the field of MEMS (micro electro-mechanical systems), comes in handy.

In AR/VR, optics have fundamentally two roles. 1) To create optical sensing of the surroundings, in order to create a digital copy of the analog world we live in, but also to enable eye tracking and use of cameras. These are all optical systems that exist today but in order to be integrated into a minimal form factor in a pair of stylish glasses, the optical systems must be as small and simple as possible, and nano-optics seem to be the answer. 2) Nano-optics are also the answer to creating thin transparent displays that give the user the AR experience. Highly precise nanostructures are used to couple the light from a projector module into your eyes.

NILT flat optics are built on both meta and diffractive optics, both diffractive technologies. We are able to combine them to find the best solution to the optical application in question. In the fall of 2021, we demonstrated a 94% absolute efficiency of both technologies. Compared to existing curved optics, our flat optics are flatter, thinner, and lighter. They have a lens simplicity never achieved before nor made available to AR/VR for mass production applications. Our technology can deliver significantly better imaging quality in AR/VR devices and have the precision and energy-efficiency needed for sensing and machine vision applications.

Reductions in SWAP (size, weight, and power reduction) are a perpetual ask when it comes to designing the next generation of a technology. How do you achieve those miniaturization goals without sacrificing performance and efficiency?

You are alluding to exactly why flat-optics are so interesting. Flat optics is born with the properties of being compact and having low weight. For many years the power reduction, or as we often address it, the optical efficiency, was not attractive. With the extreme nano-precision that we at NILT achieved, combined with our novel design rules, it is now possible for us to create flat optics with very high efficiency. So, from our perspective, it is not a question about sacrificing, we rather see nano-optics as an ideal use case for the extreme nano-precision we have developed.

The NILT flat optics platform is said to improve eye tracking, energy usage, and the overall visual experience. How did NILT identify those opportunities for improvement and then determine the best ways to address them?

The AR experience is, as already mentioned, highly dependent on optics to function. We looked at the different needs in the AR market. Some areas have a more salient need, and I believe that eye-tracking and machine vision cameras are among the first applications together with the display to make use of nano-optics. It is given that the user experience is of great importance, so the nano-optics solution must be on par with more bulky and heavy solutions based on refractive optics to the technology of choice. The AR market is a long-term play, and many generations of technology need to be launched before we reach a point where the final product is what people today think it will be. We design our nano-optics with efficiency as a key parameter on a more specific level. As little light as possible shall be lost, resulting in low absorption, low stray light. Better performing optics also means that less energy is needed. All of these are critical parameters for the creation of beautiful AR products that consumers will enjoy.

NILT announced a $31 million capital raise over the last year. How did the funding allow NILT to achieve its latest flat optics breakthrough?

Nano-optics is fundamentally changing how optics are designed. For centuries, optical systems have been designed and optimized from a refractive point of view. Adding diffractive optics to the toolbox challenges the well-established design rules. In addition, there are no foundries or injection molding companies to lean on for mass production.

With our capital raise, we have been able to build optical design and mass production capabilities of meta and diffractive optics. We are now able to design, prototype, assemble, and bring MOEs up to mass production, and the entire process is done internally. As a result, we are able to deliver MOEs to customers’ specifications in large quantities, with design to prototyping delivery in only four weeks and further redesign and turnaround in less than two weeks. The MOEs can be designed with complex phase functions, and multi-MOE stacked components can be designed to meet required specifications.

Existing flat optics for AR/VR weren’t always scalable to mass production. What is it about the NILT technological breakthrough that allows it to be reliably produced in larger quantities?

We have a deep understanding and many years of experience with nano-replication and nanoimprint, and nano-optics is the perfect use case for this technology. We build prototypes of optics using electron beam lithography, which is also the technology we use to create masters. Masters are then used in a parallel wafer-scale process, called nanoimprint lithography (NIL) for mass production. The alternative manufacturing route is to use semiconductor foundries. We believe these semiconductor foundries will suffer from being optimized for they do not offer the flexibility that is needed in optics. When we do the math, our approach has an attractive cost of ownership structure, and our speed is unmatched. We can realize prototypes in a matter of weeks, and we can produce optics in volumes in a matter of a few months after we have the design.

The NILT flat optics technology could be in the hands — or on the eyes, rather — of consumers in the coming year or two. In what markets or specific applications do you see this technology elevating the AR/VR experience?

I think it will be the brand names and the integrators that will make the call in the end, but 3D sensing, machine vision cameras, and eye-tracking are all candidates to be “first movers” in optical systems. Today, many AR solutions already use diffractive waveguides in the displays, and in this sense, flat optics is already here.

Given the advances made in size, weight, energy usage, and visual performance, how can we expect flat optics to change or improve the trajectory of AR/VR?

I think flat optics is the reason that AR eventually will succeed. Everyone is looking into this. If not, they will soon. Nano-optics has proven itself, and in the fall of 2021, we at NILT demonstrated several announcements about flat optics with high efficiencies that are ready for commercial production. The cool features and the sexiness of elegant glasses with astonishing performance simply require compact and elegant optical solutions. I believe nano-optics is the way to go.

And even still, there’d be room for generational growth. What do you anticipate will be the next ask for improving upon existing AR/VR technology?

When nano-optics mature, I foresee that it will be implemented everywhere. The form factor is too attractive not to. In addition, we have not even talked about what nano-optics can do in terms of added functionalities that only very complex, bulky, and heavy optical systems can do. One example is nano-optics capabilities to do polarization-specific manipulation of the light. But the implications of this we will have to save for another day.