Nanopositioning And Laser Measurement: The Twin Engines Of Modern Imaging

By John Oncea, Editor

Discover how nanometer-scale positioning and advanced laser measurement are transforming microscopy, driving progress in semiconductor, biotech, and imaging research.

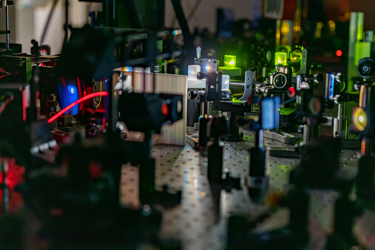

As modern research and manufacturing race toward ever-smaller structures and higher data fidelity, microscopy stands at the heart of technological progress in photonics, quantum science, semiconductors, and biotechnology. Two critical trends now define this rapidly evolving landscape: nanometer-precision positioning and the integration of advanced laser measurement systems.

Together, these trends are not only enabling sharper images and more reliable data but also fueling fundamental advances in next-generation devices and materials. Here’s how engineers can harness these interconnected breakthroughs.

Revolutionizing Control At The Nanoscale

Nanopositioning systems – devices capable of moving samples or instrumentation with sub-nanometer accuracy – have fundamentally changed the capabilities of microscopy in the scientific and industrial world. These systems rely on technologies such as piezoelectric actuators, capacitive sensing, and advanced closed-loop feedback to achieve unprecedented precision and repeatability.

The momentum behind this field continues to grow rapidly. According to a 2025 market analysis, application needs in atomic force microscopy (AFM), scanning tunneling microscopy (STM), and advanced imaging have driven nanopositioning systems ever deeper into research labs and production lines, supporting everything from fiber alignment to quantum device fabrication. Miniaturized actuators and enhanced automation are opening new niches, including microfluidics, biological imaging, and emerging quantum computing workflows, according to Cognitive Market Research.

Engineering Trends: Automation, AI, And Integration

Three key engineering shifts are converging within the nanopositioning landscape. First, the ongoing trend of miniaturization, enabled by enhanced materials and fabrication techniques, has yielded compact and robust systems that integrate seamlessly with advanced microscopes and nanofabrication tools.

Second, automation and AI are becoming more prevalent, as machine learning and AI-driven feedback algorithms blur the line between operator-driven and fully autonomous operation. Real-time optimization and reduced human intervention mean more reproducible and scalable results, which is significant for a variety of research settings.

Third, advances in materials science are bolstering environmental stability, ensuring nanopositioners operate reliably under environmental extremes, a critical component for maintaining accuracy in long-term or high-throughput experiments. When combined, these trends both increase accessibility for smaller laboratories and accelerate efficiency across industrial and biotechnology contexts.

Rise Of Interdisciplinary Applications

The demand for nanopositioning is experiencing particularly strong growth in several interdisciplinary application areas. Within semiconductor manufacturing, wafer alignment and nanolithography require ultra-precise motion control. In biotechnology, applications such as DNA sequencing, high-content imaging, and cell manipulation all depend on consistent, nanoscale movements.

Medical diagnostics are also benefiting, as precise sample control is foundational for the latest diagnostic technologies, directly impacting early detection and the advancement of new therapeutic modalities.

Precision Laser Measurement – The Engine Of Reliable Data

While precision motion is necessary for high-resolution imaging, it is only meaningful when paired with reliable, quantifiable illumination. The accuracy and stability of laser light – particularly in fluorescence and confocal microscopy – directly determine the quality and reproducibility of measured signals.

Research-intensive laboratories are increasingly integrating sophisticated laser power meters, beam profiling systems, and real-time monitoring directly into imaging setups. Such integration ensures that subtle photonic effects are measured against known reference levels and calibration routines, which is critical when striving for reproducibility and objectivity in complex microscopy environments.

Technological Advancements

Over the past year, innovations in laser measurement have targeted the evolving needs of high-speed, multiplexed, and high-throughput imaging. New sensors and controllers now deliver real-time performance metrics, which makes it possible to adjust laser intensity dynamically and minimize both sample damage and image artefacts.

Systems also have made leaps in sensitivity and dynamic range, meaning signals as weak as those from single molecules can be reliably captured across diverse settings, from live-cell imaging to quantum photonics. Additionally, automation and user-friendliness have become primary goals: calibration tasks once reserved for highly skilled specialists are now increasingly embedded within the imaging workflow, which dramatically reduces human error and enables true unattended operation, according to NIH.

Meeting Demands Across Disciplines

This heightened focus on rigorous, traceable measurement is serving a growing number of strategic needs. Quantitative imaging in fields like modern biology and materials science now demands not only high spatial and temporal resolution but also quantitative intensity measurements that allow for statistically meaningful analysis.

Furthermore, as light sources grow more powerful, safety and compliance concerns require constant monitoring to protect both users and fragile biological samples. Finally, the growing size and complexity of imaging datasets mean that repeatable, automated calibration routines are crucial to drawing valid, large-scale conclusions in both academic and industrial research.

Looking Ahead: What Photonics Engineers Should Watch

As the disciplines of photonics, quantum engineering, and molecular biology become ever more intertwined, there is a clear need for systems that not only operate at the extremes of precision and sensitivity but also deliver fault-tolerant, scalable, and autonomous workflows.

Both nanopositioning and laser measurement are now benefiting from the development of integrated platforms that unify hardware and software, which is speeding up experimental turnaround times and dramatically elevating the reproducibility of complex experiments. In parallel, data-driven optimization techniques – such as real-time analytics, AI-guided calibration measures, and feedback mechanisms – are enabling systems to operate much closer to their theoretical performance limits while opening fundamentally new frontiers for scientific discovery, according to Cognitive Market Research.

As automation becomes more common in research laboratories and production lines alike, possessing interdisciplinary fluency will become one of the key strengths for successful engineers. Once considered specialized equipment topics, issues like precision positioning, advanced measurement, and intelligent feedback control are now at the center of the photonics and imaging revolution, shaping the future of how discoveries are made.