Metrology In Photonics: Standardization, Calibration, And Quality Control

By John Oncea, Editor

Some consider metrology to be the oldest science with its origins dating back to the earliest civilizations. It has evolved over the years, from cubits to sundials to atomic clocks. Let’s take a look at this science, specifically optical measurement techniques.

George, Fiona, and Elvis sit in a sort of non-descript beige room in a lab owned by the Department of Commerce on the campus of the National Institute of Standards and Technology (NIST) in Boulder, CO. All three “have quirks and personalities,” says physicist Jeff Sherman.

They also share a common job: protecting three high-precision atomic clocks that “are just part of the 21-clock ensemble NIST uses to generate the official time,” reports NPR. In case you haven’t figured it out, George, Fiona, and Elvis aren’t NIST employees, they’re names given to the boxes that the atomic clocks are stored in.

If you were to look through a little hole into any of the three boxes, you’d see a pink glow coming from the atoms of hydrogen. “These three clocks tick using hydrogen atoms” that “are excited using radiofrequency energy and then sent into a chamber,” reports NPR. “Once inside, they decay, emitting a specific frequency of light.”

The process can be likened to striking an atomic tuning fork, says Sherman. As the hydrogen emits a tone of light, the “rest of the clock ‘is an instrument that tries to sample — tries to listen — to a little bit of that light and count the cycles of oscillation in that light,’” explains NPR. “Those light cycles are the ‘tick’ of the clock.

“By averaging a subset of the 21 clocks together, NIST has created a system that can count the time to within one quadrillionth of a second. That means the government’s clock can keep time to within a second over about 30 million years.”

As impressive as that is, consider that if you miss one of those little trillionth seconds, you don’t know what time it is anymore. “In exchange for this wonderful idea,” Sherman says, “you're now beholden to count forever and not lose track.”

And those atomic clocks – protected by our friends George, Fiona, and Elvis – are one mind-blowing example of metrology, the science of measurement embracing both experimental and theoretical determinations at any level of uncertainty in any field of science and technology.

How Metrology Measures Up

The history of measurement can be traced back to the beginning of human civilization. In the past, people used seeds, beans, and grains as weights and body parts like the forearm and thumb as length units. As time passed, various societies introduced their own measurement systems, such as the Roman uncia and mille, and the Anglo-Saxon system in England.

“With the continuous progress of technology, metrology testing will play a vital role in various industries and scientific disciplines, driving sustainable improvements and ensuring reliable measurements,” writes AZoNano. “3D measurements will become commonplace, enabling real-time corrections and optimization during manufacturing. Quality control managers will face new challenges but also benefit from detailed data provided by advancements in 3D measurement technology. The future of metrology holds great promise for improving quality, streamlining processes, and facilitating data-driven decision-making.”

The present doesn’t look too shabby, either, where metrology, which can be used either experimentally or theoretically, is widely used. In photonics, it is helping ensure the accuracy, reliability, and standardization of measurements enabling advancements in areas such as telecommunications, imaging, and optical sensing. Several benefits provided by metrology include:

- Precision Measurement Instruments: Metrology provides the foundation for the development and calibration of precision measurement instruments used in photonics. Instruments like spectrometers, interferometers, and photodetectors rely on accurate measurements to ensure the precision and reliability of photonics systems.

- Calibration of Optical Devices: Metrology is essential for calibrating optical devices and components used in photonics applications. This includes lasers, lenses, mirrors, and other optical elements. Calibration ensures that these components perform accurately and consistently.

- Standardization: Metrology contributes to the establishment of standards for photonics devices and systems. Standardization allows for consistency in measurements and facilitates interoperability between different components and instruments from various manufacturers.

- Characterization of Optical Materials: Metrology is used to characterize the properties of optical materials, such as refractive index, absorption coefficients, and dispersion. This information is critical in designing and manufacturing photonics components with specific optical properties.

- Quality Control: In photonics manufacturing, metrology is employed for quality control purposes. Precise measurements ensure that components meet specifications and perform within desired tolerances. This is crucial for the production of reliable and high-performance photonics devices.

- Interferometry: Interferometric techniques, a subset of metrology, are widely used in photonics for measuring small displacements, wavelengths, and refractive indices with high precision. Interferometers are essential tools for characterizing the optical properties of materials and components.

- Quantum Metrology: With advancements in quantum technologies, quantum metrology is emerging as a powerful tool for enhancing the precision of optical measurements. Quantum-enhanced sensors can provide more accurate measurements of various optical parameters.

More Specifically, Optical Metrology

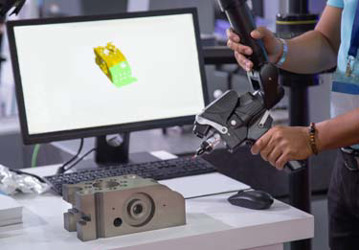

Optical metrology is a specialized field of measurement that employs optical technologies and principles to measure physical quantities with exceptional accuracy. This branch of science utilizes light from optical sources to determine various parameters such as distance, shape, surface roughness, and more. There are several techniques and instruments that use these optical sources to produce precise measurements.

“Common techniques include interferometry, which involves the interference of light waves to measure variations in distance or surface shape,” writes Electro Optics. “Laser-based distance measurement systems are used for distance measurements in applications such as manufacturing, while holographic techniques are used for precision measurements and visualization of 3D objects. Optical profilometry measures surface profiles and roughness using optical instruments. It is commonly used in industries such as microelectronics and optics manufacturing.”

Optical metrology is a non-contact and highly precise method used in various industries such as manufacturing, aerospace, automotive, medicine, and research. It is a valuable tool for quality control and detailed measurements.

Optical metrology equipment uses various optical components, which are selected based on the specific application and technique. Lenses, mirrors, polarizers, analyzers, prisms, optical filters, optical detectors such as photodiodes or charge-coupled devices (CCDs), collimators, and diffraction gratings are some of the common optical components used in optical metrology.

As mentioned earlier, optical metrology doesn't require physical contact between the measuring device and the object being measured. This helps to reduce the risk of damage to the object and results in highly accurate measurements, making them a valuable tool for applications that require precise measurements. The technology is also fast, providing quick measurements, which is useful for applications that require rapid measurements.

However, like any technology, optical metrology has some disadvantages. Environmental changes like temperature, humidity, and vibration can affect the accuracy of the measurements. Certain methods may also have a limited range, making it difficult to measure large objects or surfaces. Additionally, the cost of optical measuring equipment can be high, making it less accessible for some applications or industries.