Machine Vision Applications Of Hyperspectral Imaging

By John Oncea, Editor

Hyperspectral imaging is emerging as a powerful complementary technology to traditional machine vision, offering enhanced capabilities for automated inspection, sorting, and quality control across various industries.

Machine vision has revolutionized industrial automation and quality control processes across various industries. In recent years, hyperspectral imaging (HSI) has emerged as a powerful, offering unprecedented capabilities for detecting and analyzing materials beyond what traditional machine vision systems can achieve.

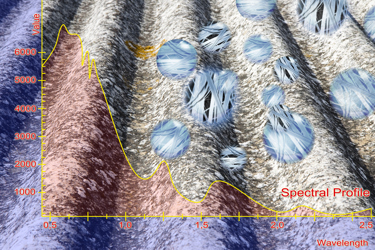

HSI is a technology that captures and processes information from across the electromagnetic spectrum, going far beyond the limitations of human vision or standard RGB cameras. While conventional machine vision systems typically use three color channels (red, green, and blue), HSI can collect data from hundreds of narrow spectral bands, providing a wealth of information about an object’s chemical composition and properties. This enhanced spectral resolution allows hyperspectral machine vision systems to detect subtle differences invisible to the human eye or traditional cameras. For example, HSI can:

- Identify different materials with similar visual appearances

- Detect chemical composition and contamination

- Analyze the internal properties of objects, not just surface characteristics

- Operate in non-visible parts of the spectrum, such as near-infrared (NIR) or short-wave infrared (SWIR)

The applications of hyperspectral machine vision are diverse and growing rapidly across industries, such as food and agriculture, detecting spoilage in fruits and vegetables, sorting food products based on quality and ripeness, and identifying foreign objects or contaminants in food processing.

In the pharmaceutical industry, it is ensuring correct pill composition, detecting manufacturing defects, and improving quality control in drug packaging. In the recycling and waste management industries, it helps sort different types of plastics and materials and identify recyclable components in mixed waste streams.

Hyperspectral machine vision is also used in medical Imaging to detect hidden cancers and other abnormalities, as well as analyze biomarkers within tumors. Finally, industrial manufacturing, where it is used for quality control for construction materials like wood and for detecting impurities, damp spots, or defects in products.

Challenges To Hyperspectral Machine Vision Implementation

One of the key advantages of HSI in machine vision is its ability to provide faster and more accurate results than human sorting or traditional vision systems. This leads to improved efficiency, reduced costs, and enhanced quality control.

However, implementing hyperspectral machine vision does come with challenges. The technology requires specialized hardware and software, and the large volumes of data generated by HSI can be computationally intensive to process in real time. Manufacturers are addressing these issues by developing faster sensors, more powerful embedded vision systems, and advanced artificial intelligence algorithms to manage complex data analysis.

As the technology continues to mature, we can expect to see wider adoption of hyperspectral machine vision across industries. The ability to see beyond human vision capabilities opens up new possibilities for automation, quality control, and material analysis that were previously impossible or impractical.

HSI represents a significant leap forward in machine vision technology. Providing detailed spectral information about materials and objects enables more sophisticated and accurate automated inspection and sorting processes. As HSI in machine vision becomes more accessible and integrated into industrial systems, it has the potential to transform quality control and automation across a wide range of industries.

How HSI And Machine Vision Work Together

HSI serves as a complementary solution to traditional machine vision technologies by expanding the range of information that can be captured and analyzed beyond what conventional systems can detect. Here’s how HSI enhances and complements traditional machine vision:

- Extended spectral range: While traditional machine vision typically operates within the visible light spectrum (400-700nm), HSI captures data from a much broader portion of the electromagnetic spectrum, including ultraviolet (UV) and infrared (IR) regions. This extended range allows for the detection of properties and characteristics that are not visible to the human eye or conventional cameras.

- Material identification and classification: HSI enables the identification and classification of different materials based on their unique spectral signatures. This capability goes beyond simple color or shape recognition, allowing for more precise and detailed analysis of objects and substances.

- Non-destructive analysis: HSI provides a non-destructive way to analyze materials and their properties, making it particularly useful in industries where product integrity is crucial, such as pharmaceuticals and food production.

- Enhanced quality control: Conventional vision systems often struggle to differentiate items with similar colors or appearances. Hyperspectral data, combined with spatial pattern recognition algorithms, can detect a wide range of materials, patterns, coatings, defects, and contaminants.

- Chemical composition analysis: HSI can provide information about the chemical composition of materials, which is particularly valuable in industries like pharmaceuticals, food production, and recycling.

- Improved sorting capabilities: In applications such as food sorting or recycling, HSI can differentiate between materials that may look similar to the human eye or traditional cameras but have different spectral properties.

- Real-time analysis: Modern HSI systems can perform real-time analysis of full product streams, enabling faster and more efficient inspection processes.

By combining the strengths of traditional machine vision with the advanced capabilities of HSI, industries can achieve more comprehensive and accurate inspection, sorting, and analysis processes. This complementary approach allows for better decision-making, improved product quality, and enhanced operational efficiency across various applications.

Real World Examples Of Hyperspectral Machine Vision

Hyperspectral machine vision, as noted earlier, has found diverse applications across various fields including agriculture, mining, medical diagnostics, and remote sensing, complementing traditional machine vision in these areas.

- Agriculture and Precision Farming: HSI assists farmers in optimizing crop management. Machine vision algorithms convert hyperspectral data into valuable insights such as nitrogen, water, and chlorophyll levels, crop and weed density, and yield estimates.

- Food Industry: Hyperspectral machine vision is increasingly used for sorting food and assessing its quality. It can spot contaminants (e.g., shell fragments among nuts) and ensure product consistency.

- Mining and Geology: Determining mineral composition in mining operations is another application. HSI provides detailed spectral information, aiding in mineral identification and exploration.

- Environmental Monitoring and Ecology: Researchers use hyperspectral data to study vegetation health, monitor ecosystems, and assess environmental changes. It helps detect invasive species, track land cover changes, and assess water quality.

- Biomedical and Life Sciences: Beyond machine vision, HSI finds applications in bio-agent detection, live cell microscopy, genomics, proteomics research, and even precancerous cell detection.

HSI offers rich spectral information, enabling precise analyses and robust classifications across diverse domains. It is revolutionizing machine vision by providing a wealth of information beyond what traditional systems can detect and, as the two technologies continue to intertwine, evolve, and become more accessible, there will likely be even broader applications across various industries, enhancing quality control, process efficiency, and product safety.