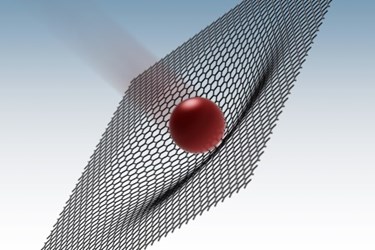

Laser-Propelled Microbullets Illustrate Graphene's Toughness

By Chuck Seegert, Ph.D.

By firing microbullets, a new laser-based system has shown that graphene is much tougher than steel. Previously, static testing had shown graphene in a positive light, but these new results demonstrate that the material could be useful for body armor or even coating spacecraft.

Graphene has been hailed as a wonder material with exemplary electrical properties and high tensile strength. Coating surfaces with graphene can improve corrosion resistance. In addition, the material has been extensively used in the diagnostic space because it can be manipulated at the nanometer scale.

One thing that hasn’t previously been tested, however, is graphene’s ability to withstand impact, according to a recent press release from Rice University. To test this ability, a team at Rice developed a special device called the laser-induced projectile impact test (LIPIT). Using a gold surface to propel laser energy, microbullets about 3.7 microns in diameter were propelled at speeds of up to 3 kilometers per second — much faster than bullets fired from a traditional firearm — at sheets of multilayer graphene.

The LIPIT device was used to test multilayer graphene with thicknesses that ranged from 10 to 100 nanometers, according to a recent study published by the team in Science. Rather than puncturing the material, the microbullets caused the graphene membrane to stretch into a cone-shaped formation. After stretching, a series of radial cracks were shown to extend out from the area surrounding the impact site. The cracks followed a somewhat crystallographic pattern and extended well beyond the site of impact. This demonstrated that the graphene stretched prior to cracking, indicating that the material distributed the stress of the projectile over a wide area.

“The game in protection is getting the stress to distribute over a large area,” said materials scientist Edwin “Ned” Thomas in the press release. “It’s a race. If the cone can move out at an appreciable velocity compared with the velocity of the projectile, the stress isn’t localized beneath the projectile.”

The speed at which tensile stress moved within graphene was calculated to be 22.2 kilometers/second, faster than any other known material, according to the press release. Additionally, the fracture patterns were indicative of a material that could be useful in body armor. The specific penetration energy for graphene was also shown to be about 10 times more than that of the common literature values for steel, according to the study.

Additionally, the researchers believe that the LIPIT device could serve as a valuable tool for testing other experimental materials.

“Before you scale a project up, you’ve got to know what will work,” Thomas said in the press release. “LIPIT lets us develop rapid methodologies to test nanoscale materials and find promising candidates. We’re working to demonstrate to NASA and the military that these microscopic tests are relevant to macroscopic properties.”

Using multiple layers of graphene is a practice that has led to interesting outcomes in other areas as well. For example, a multilayered graphene construct could lead to near-perfect crystals that might be useful for a next generation of transistors, according to a recent article on Photonics Online.

Image Credit: Jae-Hwang Lee/Rice University