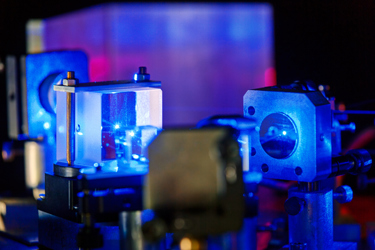

Laser Beam Measurement In Electronics & Semiconductor Manufacturing

In electronics and semiconductor manufacturing, maintaining laser performance is critical to process consistency and product quality. Over time, laser specifications can shift due to factors such as aging, thermal lensing, and environmental influences, leading to risks like interrupted production and defective parts. Gentec-EO addresses these challenges by providing NIST-traceable, high-precision laser measurement solutions tailored to industry needs.

To support manufacturing accuracy, Gentec-EO offers both spot-check and continuous in-line monitoring systems, allowing manufacturers to detect deviations early and reduce waste. Key applications include photolithography, PCB drilling, and wafer dicing, each with unique measurement needs. Gentec-EO’s UP series thermopile-based detectors, known for their high power density capacity, are particularly popular in the industry. The company also provides options for remote monitoring, Industry 4.0 integration, and fast, customizable detectors like the INTEGRA series, which combines a detector and meter into a single unit.

Explore the solutions Gentec-EO offers to meet specific requirements, such as software integration, vacuum compatibility, and high-power measurement up to 100 kW. Gentec-EO’s reliable, ISO-compliant tools enable semiconductor manufacturers to maintain strict quality standards, validate system performance, and ensure customer satisfaction.

With over 50 years of expertise and partnerships worldwide, Gentec-EO stands out as a trusted provider of innovative, adaptable solutions for laser measurement in high-stakes manufacturing environments.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Photonics Online? Subscribe today.