How Thin-Film Coating Advancements Are Improving Device Performance

By John Oncea, Editor

Thin-film coatings – crucial in telecommunications, healthcare diagnostics, consumer electronics, aerospace defense, automotive, and industrial automation – continue to evolve, and their role in enabling high-capacity data transmission and improving device functionality is becoming more prominent.

Thin-film coatings have progressed from their historical role as protective layers to become central components in modern electronics, optics, energy systems, and biomedical devices. Their ability to manage heat, improve durability, and finely control electronic and optical behavior is crucial in meeting the demands of telecommunications, aerospace, automotive, healthcare, and industrial automation.

As technological requirements for higher efficiency, miniaturization, and multifunctionality intensify, thin-film systems are evolving rapidly, bridging the gap between material science research and practical device applications.

High-Voltage And Power Electronics Advancements

In high-power electronics, thin films are pivotal for integrating wide-bandgap semiconductors such as Gallium Nitride (GaN) and Silicon Carbide (SiC). These materials, when deposited as thin films, enable higher breakdown voltages, faster switching speeds, and improved thermal management, which are essential for electric vehicle powertrains and next-generation telecommunications infrastructure, according to NIST.

Hafnium oxide (HfO₂) dielectrics, grown via atomic layer deposition (ALD), provide low leakage currents and high reliability in miniaturized gate stacks, supporting continued efficiency improvements in transistor and device architectures, according to ALD 2025. By enabling compact, high-performance power devices, these thin-film systems contribute to energy efficiency gains that complement broader trends in semiconductor scaling without directly extending Moore’s Law.

Optical Systems And Photonics

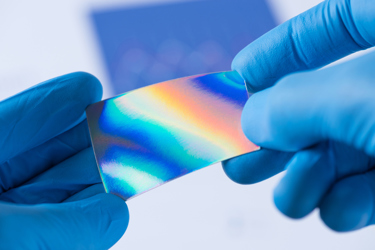

Thin films play a transformative role in optical systems, from lenses and imaging arrays to high-resolution displays and laser-based instrumentation. Precision coatings modulate reflection, transmission, and absorption, improving color fidelity and image clarity while reducing unwanted reflections.

Magnetron sputtering techniques allow for dense, durable films that withstand abrasion, humidity, and thermal cycling, critical for aerospace optical assemblies and medical diagnostic instruments, according to NASA's Jessica Gaskin. Recent advances in material selection and deposition control enable multi-layer interference coatings that optimize device performance for compact, high-resolution optical applications.

Protective And Functional Coatings

Beyond electrical and optical properties, thin films extend component lifespan through wear resistance, corrosion protection, and self-lubricating architectures. Multilayer coatings incorporating hard phases like titanium nitride (TiN) and lubricating layers reduce erosion and friction on turbine blades, surgical tools, and industrial machinery, according to NIST.

Emerging smart coatings can adapt dynamically to environmental changes, such as humidity or mechanical stress, providing self-healing or protective behavior. While still largely in experimental or early commercial stages, these functional coatings hold promise for enhancing reliability and reducing maintenance downtime in critical systems, according to MDPI.

Thin-Film Sensors And Flexible Electronics

Thin films now serve as the active layer in gas, chemical, and biomedical sensors. ALD-grown oxide films and polymer-based coatings offer high sensitivity, enabling continuous patient monitoring devices and environmental detectors, according to ScienceDirect.

Additionally, flexible and stretchable thin-film electronics allow conformal integration onto non-planar surfaces, supporting wearable devices, foldable displays, and medical implants. The combination of mechanical compliance and functional performance positions these thin films as a core enabling technology in next-generation sensor networks.

Deposition Technologies: ALD And CVD

Atomic Layer Deposition (ALD) remains a cornerstone of thin-film precision, providing atomic-scale uniformity and thickness control. Area-selective ALD enables localized deposition on complex device architectures, critical for miniaturized and highly integrated electronic and photonic systems, according to Stanford University.

Complementary Chemical Vapor Deposition (CVD) techniques, including plasma-enhanced and metal-organic approaches, allow high-quality coatings on sensitive substrates, such as polymers for flexible electronics, according to ACS Publications. These deposition methods are instrumental in creating heterostructures and multilayer films that support both conventional and emerging applications.

AI And Process Intelligence In Thin-Film Manufacturing

The integration of artificial intelligence (AI) and data analytics into thin-film manufacturing has accelerated process optimization. Machine learning algorithms now monitor deposition in real time, adjusting parameters to minimize defects and maximize throughput. AI-based material screening predicts performance and optimal processing conditions for new thin-film candidates, reducing experimental cycles, according to NIST. These digital tools enhance scalability, product consistency, and efficiency, particularly in semiconductor, photovoltaic, and biomedical device production.

Sustainability And Green Manufacturing

Sustainable approaches are increasingly integral to thin-film production. Low-temperature deposition, water-based precursors, and recycling protocols reduce environmental impact while maintaining performance standards, according to Wiley Online Library. The industry trend toward energy-efficient, automated deposition systems ensures process repeatability while minimizing resource consumption. Emerging green chemistries and digital control systems support the development of environmentally responsible thin-film coatings that meet both technical and regulatory demands.

Industry Impact And Future Outlook

Thin-film coatings have become enablers of high-performance, multifunctional systems across multiple sectors. In telecommunications and data centers, thin films improve heat management, electromagnetic interference reduction, and signal integrity at increasing frequencies, according to APS. Aerospace applications rely on abrasion- and radiation-resistant coatings for satellites and deep-space probes. In healthcare, biocompatible and antimicrobial thin films enhance the safety of surgical instruments, catheters, and implantable devices. Automotive and industrial automation benefit from wear-resistant coatings that reduce downtime, operational costs, and resource consumption.

Looking ahead, advances in material science, deposition precision, and AI-driven process control will continue to redefine thin-film capabilities. The convergence of multifunctionality, sustainability, and digital manufacturing promises coatings that not only protect and enhance devices but also enable new functionalities and device architectures. As thin-film technologies evolve, they will remain at the forefront of innovation in electronics, optics, energy management, and biomedical applications, shaping a more efficient, resilient, and connected technological landscape.