How Cleanroom Testing Protects Sensitive Optics And Lasers

By Brent Hart, Technical Safety Services

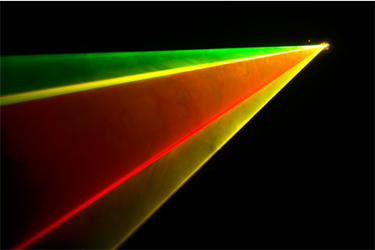

Contamination is one of the most serious risks in photonics. Unlike mechanical systems, where small imperfections can be tolerated, optics and lasers operate at scales where even a submicron particle can significantly impact performance. Engineers know that a pristine optical path is critical, but keeping it that way requires rigorous cleanroom testing, precise handling, and an understanding of how contaminants interact with light at both the particulate and molecular levels.

Why Microscopic Particles Matter

Dust may look harmless to the eye, but in photonics, size matters. Particles as small as 0.2 microns can scatter light and reduce transmission efficiency. At higher laser powers, even tiny particulates absorb energy, heating unevenly and creating localized defects. A hot spot of just a few microns can exceed laser-induced damage thresholds (LIDT), leading to coating ablation or micro-pitting that shortens the lifetime of an optic. In lithography or metrology systems, scattered light from a single speck reduces resolution and interferes with critical alignment tolerances.

The Overlooked Challenge Of Molecular Films

If particulates are the obvious enemy, molecular films are the stealth threat. Outgassing from cleaning solvents, adhesives, or polymer components can deposit monolayers of hydrocarbons across a lens or mirror. These thin films increase absorption at certain wavelengths, shifting coating performance and accelerating thermal degradation in high-power laser applications. Because the films are measured in nanometers, they often remain invisible until performance has already dropped. Detecting them requires specialized surface analysis tools, which are only dependable inside cleanroom environments.

Cleanroom Testing And Why It Matters

Cleanroom testing provides more than a dust-free workspace. ISO 14644 classifications set allowable particle counts, with Class 5 (equivalent to the older Class 100) often required for sensitive optics. Within these environments, particle counters and light-scattering instruments reveal contamination that would be impossible to detect otherwise. Engineers routinely perform scattering and absorption tests to quantify how surfaces interact with incident light, catching defects before deployment. Some facilities also use their controlled space for cold storage repair, where damaged or aging optics can be restored without introducing secondary contamination.

Standards And Industry Practice

Photonic components used in aerospace, semiconductors, and defense projects often need to meet even stricter standards than ISO minimums. For example, MIL-STD cleanliness requirements define particulate and molecular contamination limits for mission-critical optics, recognizing that once hardware is launched or deployed, maintenance isn’t an option. Meeting these standards requires discipline not only in testing but also in handling protocols, packaging design, and operator training. These practices are survival tools for high-value systems.

How Testing Protects Performance

The two most common cleanroom optical tests focus on scattering and absorption. Scattering tests use laser beams at operational wavelengths to detect whether particulates or micro-defects are redirecting energy. Absorption testing highlights hot spots where contaminants absorb more power than the surrounding surface, often at levels invisible to human inspection. By running these tests in cleanroom conditions, engineers separate true optical performance from environmental noise, ensuring reliable baseline measurements.

Best Practices That Keep Contamination Low

Standards are only part of the picture. Execution matters. Handling optics with nitrile or powder-free gloves prevents oil transfer. Using antistatic garments reduces airborne fibers. Even the choice of cleaning agents is critical; residue left by improper solvents can be just as harmful as the debris it was meant to remove. Storage protocols are equally important. Optics are best kept in sealed, low-outgassing containers, with exposure to ambient air minimized. The chain of custody from manufacture to deployment must be controlled, or contaminants can slip in unnoticed.

Why Long-Term Reliability Depends On Cleanroom Discipline

The push for rigorous contamination control comes from the environments where photonics is deployed. Spaceborne telescopes, high-volume lithography tools, and directed-energy systems are not easily serviced. A flaw introduced before launch or installation remains there indefinitely, slowly degrading system performance. The cost of downtime in these fields dwarfs the investment required for cleanroom infrastructure. For engineers, it’s not about over-engineering; it’s about preventing the avoidable failure of multimillion-dollar systems.

Optics and lasers succeed only when precision is preserved, and precision disappears quickly in the presence of contaminants. Micron-scale particulates scatter and heat light paths; nanometer-scale films absorb and distort transmission. Cleanroom testing, guided by ISO and military standards, provides the environment and tools to identify these risks before they matter. Engineers who embrace strict handling, thorough testing, and disciplined storage practices give their systems the best chance of long-term success. In photonics, contamination control isn’t a secondary concern — it’s one of the most important factors in protecting the performance and lifetime of high-value optical technology.

About The Author

Brent Hart, Vice President of Strategic Initiatives at Technical Safety Services, began his career with TSS nearly 18 years ago as a technician. With a background in Engineering Physics and Mathematics, he advanced through field and operations roles to become CEO of the company’s portfolio before taking on his current role. Brent is passionate about uniting the companies as one team and creating opportunities for employee growth as they continue their trajectory as the nation’s leading service provider.

Sources

- https://labproinc.com/blogs/cleanroom-and-critical-environment/top-contamination-culprits-in-cleanrooms-and-how-to-avoid-them

- https://www.pmeasuring.com/airborne-molecular-contamination-monitoring-amc-precision-optics/

- https://ijpc.com/Products/