Foil-Based Ultraviolet LEDs Purify Water, Kill Pathogens

By Jof Enriquez,

Follow me on Twitter @jofenriq

Researchers at Ohio State University have successfully demonstrated a technique to grow nanowire light-emitting diodes (LEDs) on thin metal foils. These unique deep-ultraviolet (DUV) LEDs are viable alternatives to conventional UV lamps for water, food, and medical equipment sterilization.

UV lamps have long been utilized for military and commercial applications for their effectiveness in detecting and killing pathogens. However, due to certain disadvantages, such as the risk for mercurial contamination, DUV-LEDs are generating great interest as a safer alternative.

“Right now, if you want to make deep ultraviolet light, you’ve got to use mercury lamps,” said Roberto Myers, associate professor of materials science and engineering at Ohio State, in a news release. “Mercury is toxic and the lamps are bulky and electrically inefficient. LEDs, on the other hand, are really efficient, so if we could make UV LEDs that are safe and portable and cheap, we could make safe drinking water wherever we need it.”

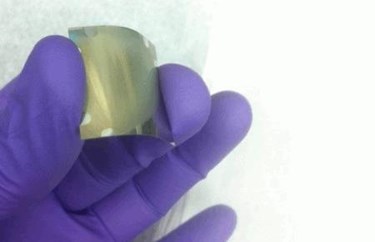

Other scientists have successfully made DUV-LEDs using extremely pure, rigid single-crystal semiconductors as substrates, but these are costly to fabricate. In building a more cost-effective light source, Myers and colleagues decided to use molecular beam epitaxy (MBE) — a long-established technique of growing very thin epitaxial layers of semiconductor crystals and nanostructures — on thin, lightweight, and flexible metal foils.

"Using molecular beam epitaxy, self-assembled AlGaN [aluminum gallium nitride] nanowires are grown directly on Ta [tantalum] and Ti [titanium] foils. Scanning electron microscopy shows that the nanowires are locally textured with the underlying metallic grains," the researchers wrote in the journal Applied Physics Letters.

The nanowires, which measure 200 nanometers tall and about 20-50 nanometers in diameter — thousands of times narrower than a human hair — lit up nearly as brightly as those manufactured on the more expensive and less flexible single-crystal silicon, according to the release.

The study abstract further explains, "Photoluminescence spectra of GaNnanowires grown on metal foils are comparable to GaNnanowires grown on single crystal Si wafers. Similarly, photoluminescence lifetimes do not vary significantly between these samples. Operational AlGaNlight emitting diodes are grown directly on flexible Ta foil with an electroluminescence peak emission of ~350 nm and a turn-on voltage of ~5 V. These results pave the way for roll-to-roll manufacturing of solid state optoelectronics."

The researchers, whose work was supported by the U.S. Army Research Office and by the National Science Foundation, will next test their method on foils made up of more common metals like steel and aluminum, and attempt to make their novel LEDs shine brighter.