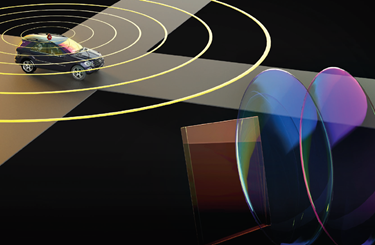

Dual-Property Coating Prevents Fogging, Unwanted Reflections For LiDAR Applications

By John Oncea, Editor

Using advanced plasma-ion-assisted deposition technology, a team of researchers created an effective combination of antireflective double-nanostructure together with an antifog coating which provides long-term reliability and is suitable for LiDAR applications.

Optical systems, such as those used in autonomous cars, require a specialized antireflective coating to optimize performance and minimize reflectance from optical surfaces. Then there’s fogging which can cause light scattering, reducing image quality as well as other functional properties.

To tackle this problem, a combination of antireflective double nanostructures on top of an antifog coating has been developed by Anne Gärtner and a team of researchers from the Fraunhofer Institute for Applied Optics and Precision Engineering IOF (Fraunhofer IOF) and Friedrich Schiller University Jena, reports Fraunhofer IOF.

“Walking into a warm room from the cold outside can cause glasses to fog up, blinding the user,” says Gärtner. “The same can happen to sensors such as the LiDAR systems used in autonomous cars. Surfaces must remain highly transparent, even if fogging occurs, so that functionality is maintained.”

Gärtner and her team – lrike Schulz, Ahmad Sabbagh, Friedrich Rickelt, Astrid Bingel, Sabrina Wolleb, Sven Schröder, and Andreas Tünnermann – developed their optical coating system which, according to a paper published by Optica, combined porous silicon dioxide nanostructures with a polymer film.

“The polymer film prevents fogging, while the nanostructures at the same time reduce reflections,” the Fraunhofer IOF release notes. “Although the coatings described in the paper were developed specifically for LiDAR systems, the technology can be tailored for many different applications.”

ScienceDaily reports the coating system was developed in response to a need identified by Leica Geosystems, a developer of airborne lidar measurement systems that are used for terrain and city mapping. Scientists there noticed fogging can occur on optical surfaces exposed to extreme temperature differences between the measuring system and the environment. This can prove disastrous for autonomous cars using LiDAR.

“The optical coating developed by the team is a multi-layered system of nanostructures created on top of each other,” writes DesignNews. “The process involved etching a nanostructure into the antifog coating and then fabricating a second nanostructure on top.”

Gärtner’s team used a polymer that prevents fogging on an optical surface by acting as a water reservoir. “However, differences in the refractive indices of the polymer material and the surrounding air lead to unwanted reflections and ghost light,” she said. “To prevent these reflections, we combined the antifog film with very small structures – up to 320 nm high – to create an anti-reflective effect together with water permeability.” The newly created coating system combines anti-fogging and anti-reflective properties, something not previously feasible.

The researchers carried out extensive tests to confirm the efficacy of their multi-layer coating system in terms of anti-reflection and antifogging effects. To measure these properties, they used a spectrophotometer to measure reflectance, and a fogging test to assess antifogging properties. The results showed that the multi-layer system provided excellent antireflection over a wide spectral range, which could not be achieved with any single nanostructure-based coating. The fogging test also revealed that the nanostructures did not affect the antifogging properties of the coating system.

Beyond autonomous cars, this technology can be applied to other applications such as smartphone cameras, adaptive lighting systems, and quantum computers. The researchers are now exploring how this coating technology can be used to expand and improve upon existing technologies in these industries.

“Optical systems are becoming more and more complex and thus the demands on image quality are also increasing,” said Gärtner. “With nanostructures, anti-reflective properties can be achieved with impressive results that are often not feasible with conventional coatings. With the fundamental understanding we gained over the recent years, we are confident that we can bring nanostructured coatings to many real-world applications.”