Custom Foundry Services

Sensors Unlimited offers Trusted Foundry III-V wafer services, from fabrication to testing, enabling high-performance infrared devices for commercial, military, and space applications without in-house manufacturing.

Visit for more details:

https://www.sensorsinc.com/custom/fabrication

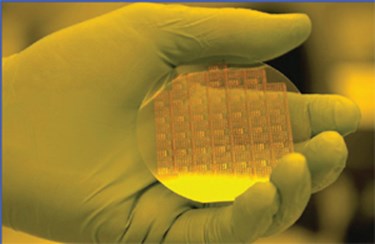

SUI’s facility supports 50 mm, 75 mm, and 100 mm diameter III-V wafers, including InGaAs/InP and InSb materials. Additionally, they provide indium bumping services for silicon wafers up to 200 mm in diameter. Customers can choose a complete end-to-end manufacturing solution or select specific processes to meet project needs.

Available wafer processes include photolithography projection, wet and plasma (dry) etching, metallization, lap and polish, metrology, epitaxy, reactor diffusion, device singulation, indium bumping, hybridization, and final packaging. Comprehensive electrical, electro-optical, environmental, and reliability testing services are also offered, ensuring device performance and durability. Data packaging and secure file transfer are included to support design verification and production documentation.

With this broad capabilities suite, SUI enables the development of infrared solutions for terrestrial and space-based applications, aligning with customer requirements for quality, reliability, and scalability. RFQs are now being accepted, and more details are available through the Sensors Unlimited website, providing a streamlined path for organizations seeking advanced IR manufacturing expertise and trusted supply chain support.