Case Study: Extended-Length LED Light Engines Speed Production, Cut Costs

By Del Williams

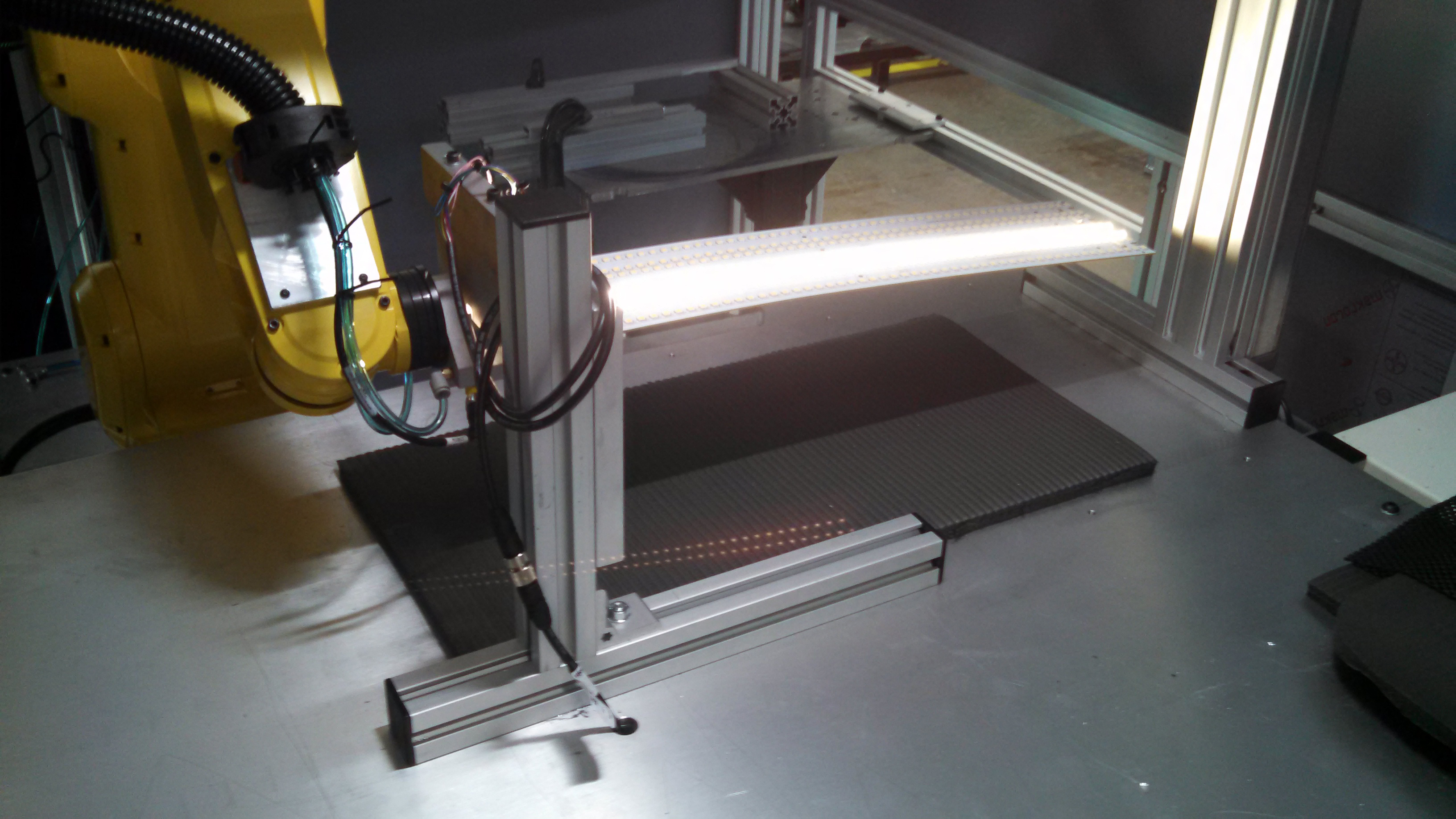

For LED light fixture manufacturers who create linear products — such as replacements for fluorescent lighting — new light engines that are up to 48 inches long and 15 inches wide allow for the quicker, easier, and therefore cheaper assembly.

Instead of two, four, or even more light engines wired together to operate linear or other larger LED fixtures, a lighting manufacturer now can connect the LED lamps to a single circuit board, thereby providing significant savings on labor, components, and assembly time.

Acra Phenolic of Traverse City, Mich., a supplier of new and retrofit interior LED lighting for the office space and manufacturing sectors, has seen significant savings by becoming an early adopter of this technology advancement.

“On the average four-foot linear LED fixture, we’re saving at least $3.50 on each unit,” says Tom Kearney, COO.

Kearney saw the need for interior lighting that was not only brighter, but also more efficient, in the typical manufacturing plant and office space. His solution was to replace T5HO lighting with more efficient LED lamps that have a life expectancy of 100,000 hours.

“I thought there was considerable room for improvement through upgrading to LED lighting, especially in business and industrial facilities where the high-pressure sodium or fluorescent lighting is often horrible,” he says. “The longer LED circuit board has added to that opportunity.”

The conventional light engine — the circuit board used to power more efficient and longer-lasting LED lamps — was in the past limited to approximately two feet in length. This meant that the assembly of linear LED fixtures, such as the four- or eight-foot models that are typically used to replace fluorescent lights, would require two or four boards attached in series, or parallel end-to-end.

As Kearney explains, with the introduction of the extended-length light engines, it takes just one board to power a typical four-foot linear LED fixture, and just two boards for an eight-footer.

“Since each board contains connectors at each end, by using a single, extended-length board for a typical four-foot fixture, I’m saving six to eight connectors on each one. In addition, I’m probably seeing a 20 to 25 percent savings on labor, plus there is a considerable savings on production time,” he says.

The extended-length circuit boards are constructed by MADE (Manufacturing And Design Electronics, formerly Cl Lighting) in Auburn Hills, Mich.

Higher-Performance Lighting

Tom Kearney is an advocate of the long LED boards to replace standard T5HO lamps as the standard for his linear fixtures, since LEDs provide 25 percent better lumens per watt (lm/W) than the next closest type of light source, as well as better lumen maintenance.

“The manufacturer of the LED chips estimates mathematically that they will maintain +90 percent of their output after 60,000 hours of operation, and +70 percent after 200,000 hours of operation,” Kearney says.

Comparatively, standard metal halide or high-pressure sodium lamps provide only 50 percent of their initial light output in as little as 8,000 to 10,000 hours — or 36 months of service — and then require replacement. Kearney adds that, when the type of light he recommends has operated for a year, it maintains a higher level of lumens per watt than any other light source currently available.

“Ironically, with traditional light sources you use the same amount of energy while getting less light output,” Kearney says. “Fixtures using LEDs see a much smaller reduction of light output over the same period of time, and that provides additional energy savings as the years go by.”

About The Author

Del Williams is a technical writer based in Torrance, Calif. He writes about health, business, technology, and educational issues. Williams holds a M.A. in English from California State University, Dominguez Hills.