Capture All In One Shot For VIS And NIR imaging By BaySpec's GoldenEyeTM!

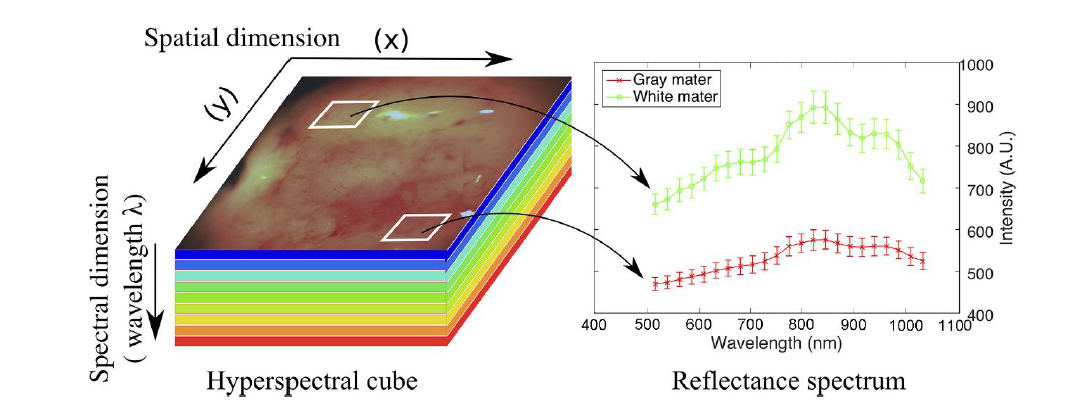

Snapshot hyperspectral imaging is a valuable technique for revealing imaging data the human eyes cannot see. The hyperspectral imager divides the light spectrum into many narrow wavelength bands, capturing the spectral signatures from an object. The spectral signatures show a spectroscopic fingerprint, revealing extremely detailed information about the material’s chemical composition of the imaged object. This spectral fingerprint allows for the identification and classification of objects, especially those in the longer wavelengths which more prominently reveal the spectral fingerprint. Traditionally, the applications have been limited as legacy hyperspectral imaging systems were bulky, heavy, and costly. With the flexibility of having a smaller and more compact imager, applications for hyperspectral imaging can be easily integrated in a wide range of areas, such as clinical research and diagnosis, fluorescence imaging, machine vision and industrial inspection, food safety and evaluation, as well as security and forensic science.

BaySpec’s snapshot hyperspectral imager, GoldenEye™, breaks tradition of the cumbersome imaging instrumentation, and is made for durability and reliability in a compact, lightweight, and easy one-shot operation design. BaySpec’s GoldenEye™ takes its name from the extraordinary vision of ducks whose golden eyes have a field vision of nearly 360 degrees and can see both near and far simultaneously, far beyond the vision of humans.

Like the golden-eyed ducks, GoldenEye™ also sees far beyond the reach of human capacity. Using BaySpec’s proprietary technology, FT-PI, this novel imager features high sensitivity, stability, and covers a large spectral range from 400 nm to 1100 nm (VIS-NIR) with approximately 50 useful spectral bands.

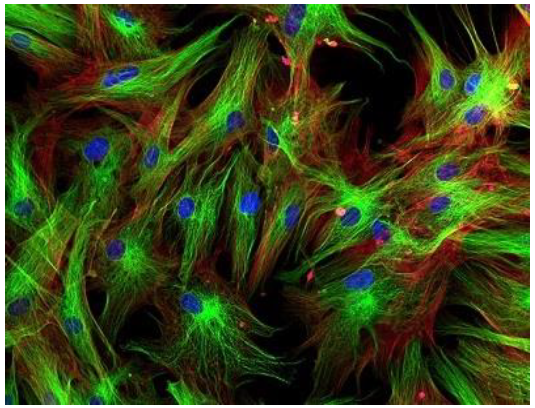

One of the highlights of BaySpec’s GoldenEyeTM is the high stability of its calibration. Unique to GoldenEye™, and better than the other hyperspectral imagers on the market, GoldenEye™ only requires a one-time factory calibration, which eliminates the need for calibration before each operational use. Eliminating the need for user calibration optimizes its performance efficiency. In addition to performance efficiency, the 50 spectral bands significantly enhance the accuracy with which assets and resources are detected and change over time. The enhanced accuracy allows identification for specific reasons for the changes, the classification of the differences, and measurement of the severity of change, not only in the physical environment but also socio-economically. Adding to the increased accuracy, GoldenEye™ has an expansive spectral range that reaches to 1100 nm. The large range increases accuracy as spectroscopic “fingerprints” tend to reside in longer wavelengths, where the color reveals the fingerprint effect more prominently. GoldenEye™ also features high sensitivity for low light level applications, since it has no small slit or aperture in its optical system, making it a great solution for fluorescence imaging.

BaySpec’s entire product line, including GoldenEye™, are designed and manufactured at BaySpec headquarters located in San Jose, California. BaySpec was founded in 1999 and is a Silicon Valley-based spectral sensing company that designs, manufactures, and markets advanced spectral instruments, which include smart handheld spectrometers, a new class of OCI™ hyperspectral imagers, novel transportable mass spectrometers, high performance UV-VIS-NIR-SWIR spectrometers, and OEM spectral engines and components. The wide range of instrumentation covers many applications uses including precision agriculture, R&D, biomedical, pharmaceuticals, chemicals, food, semiconductors, health monitoring, and the optical telecommunications industry. All of BaySpec’s instruments are 100% designed and manufactured in the USA.