Air-Cooled Black-Box Lasers

By Opotek

New air-cooled, tunable DPSS lasers eliminate the need for external support hardware, reducing overall system size and enabling cleaner, more efficient integration into OEM systems.

When original equipment manufacturers (OEMs) design and build systems, they frequently integrate technologies from third parties in areas outside their core expertise. These commercially available components are often complex and highly specialized, yet they must function as close to “black box” solutions as possible, allowing seamless integration without the need for additional programming, alignment, or engineering effort.

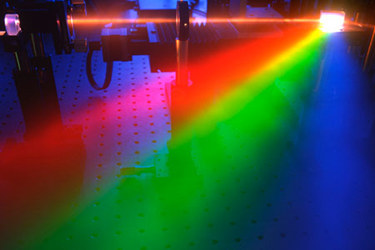

Tunable Optical Parametric Oscillators (OPO) lasers are a good example. These lasers can be “tuned” to a wide spectrum of specific wavelengths across the UV, visible, and infrared. The laser light can then be directed, or transmitted over fiber, to physically interact with matter by depositing short, intense bursts of energy into a sample.

OPO lasers are useful anywhere analytical work depends on releasing material from a surface, generating ions, or selectively exciting molecular states. As a result, they are employed in fields such as surface science, materials characterization, and chemical analysis.

Instruments that rely on laser-driven desorption or ion formations, such as laser desorption/ionization mass spectrometers, laser ablation ICP-MS systems, and laser induced breakdown spectroscopy (LIBS), benefit directly from the tunable energy these sources provide. They are also valuable in spectroscopic techniques that depend on targeted electronic or vibrational excitation, including resonant Raman, infrared spectroscopy, UV–Vis fluorescence spectroscopy, and various multiphoton or resonance-enhanced ionization methods.

In all these cases, the tunability and pulsed nature of OPO light allow product developers to match photon energy precisely to the physical interaction they require.

However, integrating a laser into a larger piece of equipment has historically been difficult.

Tunable lasers seldom achieve true “black box” simplicity because their physical footprint is substantial and they require an array of supporting components. Water-cooling units, extensive cabling, external controllers, and other auxiliary hardware are typically necessary, preventing these systems from operating as compact, self-contained devices.

Now, a new category of OPO lasers based on diode-pumped solid-state (DPSS) technology is reducing the amount of heat generated and, by extension, eliminating the need for water-cooling and other auxiliary equipment.

The new air-cooled tunable lasers are roughly the size of a couple of shoeboxes and offer performance comparable to much larger, traditionally cooled systems. The reduced electrical and mechanical complexity not only lowers operating costs but also simplifies installation, making them well-suited for OEM integration.

Steady Progress Toward Black-Box Capability

OPOs have long provided broad wavelength tunability by converting the fixed 1064 nm output of a Nd:YAG laser into a wide selectable range. However, this “tuning” requires both the pump laser and the OPO to be precisely positioned through complex manual adjustments.

Over the years, technological progress has steadily moved these systems closer to a genuine plug and play format. Current models place the laser and OPO module within a single, rigid enclosure that preserves optical alignment throughout transport and setup. Automated controls now handle crystal rotation, harmonic selection, attenuation, and routine alignment verification. In addition, many configurations support fiber-based beam delivery.

“OPOs now come as integrated, user-friendly devices that no longer require a laser engineer to set up and calibrate,” explains Dr. Mark Little, Director of Sales and Support Services at Carlsbad, CA-based OPOTEK.

These improvements simplified integration and reduced the laser head to a manageable size, but one barrier remained. Traditional configurations, even when the laser head is compact, require multiple interconnected units. These include separate motor-control electronics for the OPO, a large floor or rack-mounted power supplies, and numerous high-voltage and cooling cables.

The adoption of DPSS laser technology has effectively removed this constraint.

DPSS: The Shift To Air Cooling

Most commercial OPOs today rely on flashlamps, a high-intensity light source used to energize, or “pump,” solid-state lasers. The resulting light emits over nanosecond time periods at very high pulse energies, often in the range of several hundred millijoules.

However, reaching these energy levels requires considerable electrical power, typically involving high voltage, high current, and sizable capacitor banks. As a result, flashlamp-based systems produce intense pulses that generate substantial heat. To keep the system stable and protect components from thermal stress, they require robust water-cooling infrastructure designed to manage that heat load effectively.

DPSS-based lasers provide a much more efficient method of generating the required photons. While peak energy output levels are lower than flashlamp sources, greatly reduced heat generation allows DPSS to reach higher repetition rates or eliminate water cooling altogether.

“Historically, the adoption of diode-pumped lasers was constrained by the high cost and limited supply of high-power diode assemblies. Producing these diodes required a specialized manufacturing process, and only a small group of global suppliers had the capability to deliver devices that met the performance demands of high-energy laser systems,” says Dr. Little.

Fortunately, recent improvements in diode fabrication and supply availability have made this approach commercially viable for use in OPO lasers.

Applications that can meet their performance requirements within the energy and repetition-rate capabilities of the air-cooled DPSS design include spectroscopy and mass spectrometry. In these scenarios, the sample is stationary, and a single pulse or a small number of pulses provides the necessary information to characterize new materials by evaluating how they reflect, transmit, or absorb light.

“This type of use represents a large portion of the market,” says Dr. Little. “OEMs designing and manufacturing these kinds of systems can still access the advantages previously associated with OPOs, including broad wavelength coverage, fine tuning resolution, and a compact form factor.”

By removing integration barriers, the next generation of systems now delivers OPO-class capability in a simplified, OEM-ready package. OPOTEK’s new air-cooled DPSS laser produces 100 mJ at 1064 nm with a repetition rate of 20 Hz. This pump laser paired with an OPO delivers single digit millijoule output across a tuning range from 210 to 2200 nm and also ranges from 2300 to 4000 nm in the mid-infrared. All thermal control occurs through air cooling. The laser runs on a 24-volt DC supply and uses compact capacitor-based energy storage.

According to Dr. Little, the integrated heatsink/fan (HSF) cooling unit occupies roughly half the volume of a shoebox, which is significantly smaller than water to air heat exchangers used for flashlamp based lasers.

“For instrument manufacturers that need a tunable light source to drive an analytical process, this air-cooled DPSS configuration meets all key requirements. It supports commercialization by providing a compact, self-contained module that functions as a true black-box component,” says Dr. Little.

For OEMs, removing the water-cooling hardware cuts costs, reduces maintenance, and simplifies integration while removing any electronic safety hazards. With the core functions contained in one enclosure, developers can work with a cleaner, more manageable package.

The air-cooled design also enhances portability. Where a flashlamp system typically needs a high-voltage line and several hundred watts of power, the air-cooled unit runs on 24-volt DC and can operate from a battery. This allows deployment in locations where flashlamp systems are impractical and helps conserve space in crowded laboratory environments.

According to Dr. Little, the transition to air-cooled DPSS architecture can be compared to the shift from bulky CRT displays to thin, low-power flat screens. The underlying function remains, but the new form factor makes the technology much more practical and available to new environments.

By pairing DPSS pumping with a fully integrated OPO, OEMs can now deploy a nanosecond, wavelength-tunable source that installs as seamlessly as any other subsystem. Its compact, air-cooled architecture eliminates the limitations inherent to flashlamp-based designs, providing a practical route for product developers to incorporate true “black-box” tunable lasers into compact analytical and diagnostic instruments.

For more information, call 760-929-0770 or visit www.opotek.com.