MEMs Components Yield Tunable VCSELs

By integrating a microscopic movable mirror with a vertical-cavity surface-emitting laser, engineers have produced a tunable device for commercial applications. Part I of this two-part story discusses device design and operation.

by Daryoosh Vakhshoori and Don McDaniel, CoreTek Inc.

Contents

VCSEL Background

Micro-electro-mechanical

About the author…

The rapid implementation of WDM and DWDM communications systems has created a critical demand for reliable laser sources whose output can be broadly tuned or arbitrarily set to a given wavelength in the 1550 nm spectral communications band. Until recently, engineers have attempted to meet this need with distributed feedback (DFB) lasers and external cavity laser diodes. Unfortunately, both of these sources have significant performance limitations. Also, the external cavity laser diode has a prohibitively high cost at this time.

Now engineers at CoreTek Inc. (Burlington, MA) have combined two technologies to develop a new, robust tunable laser source. Based on micro-electro-mechanical (MEM) elements integrated with vertical cavity surface emitting lasers (VCSELs), the MEM-VCSEL offers mass-production cost benefits together with broad tuning, high singlemode power, extremely low mode noise and high polarization purity. As a result, this compact, integrated device is expected to find widespread use in long haul and metropolitan area telecommunications, as well as test and measurement applications.

VCSEL Background

The VCSEL has long been a proven laser device at shorter wavelengths (850 – 900 nm). In recent years, the technology has attracted considerable attention for possible use in WDM systems as well as other telecom and datacom applications. Unlike conventional edge-emitting diodes, the VCSEL output is perpendicular to the plane of the active junction. Avoiding the beam asymmetry, astigmatism, and other optical problems associated with laser emission from an edge facet, the VCSEL potentially offers a well-behaved, singlemode output beamideal for direct coupling into a fiber with simple optics or even butt coupling. As with conventional laser diodes, the gain bandwidth is sufficient to support tuning over tens of nanometers; if strained quantum wells are incorporated into the design, the gain bandwidth can be arbitrarily centered at a desired wavelength.

Turning these inherent benefits into a practical 1550 nm device with controlled, low-noise output has proved extremely problematic for many years. Two general design approaches have been used: electrical pumping (current injection) and optical pumping, in which the output of a shorter-wavelength laser creates the electron-hole pairs in the VCSEL quantum wells. Electrical pumping yields the simpler, more compact device, whereas optical pumping allows for a design with more quantum wells, and hence higher gain. Until recently, however, neither approach had proved capable of delivering the desired combination of low cost, high single-mode power, and reliability. The MEM-LASE is designed to address these issues.

Micro-electro-mechanical

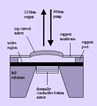

The device incorporates a concave multilayer dielectric top mirror/membrane and a thermally conductive bottom mirror to create the cavity (see Figure 1). In the first generation device, optical pump light is introduced through the curved output mirror, although future implementations will offer a pump chip integrated into the package, pumping the VCSEL through the rear plane mirror.

The key to TEM00 operation of the device is the combination of optical pumping and using the top mirror as the output coupler. Another notable feature is the use of a via hole to allow deposition of the rear cavity mirror, permitting thermally stable, long-lived operation.

Figure 1. In the MEM-LASE, a cavity defined by two dielectric thin-film mirrors is separated by a strained quantum-well active region and a small air gap. Tuning is obtained by application of a voltage between the output (curved) and rear (flat) mirror which then tunes the air gap and hence the cavity resonance.

The use of a concave mirror produces a stable resonator cavity with a high Q factor, an important advantage over earlier planar/planar configurations, which could only deliver unstable resonator conditions. Specifically, a stable resonator can be optimized to produce only well-defined, low order transverse modes. Also, by using the fiber-coupled output from a 980 nm laser diode, the optical pump produces a good spatial mode match with the TEM00 cavity mode, ensuring this is the only output mode produced by this laser.

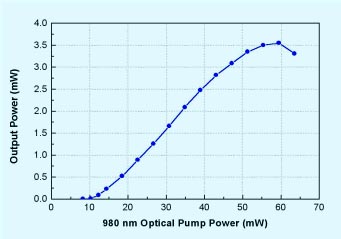

Just as important, the curvature of the mirror is designed to produce this TEM00 output with a cavity beam waist of 8 µm. This narrow beam waist was chosen to enable highly efficient coupling into single mode fibers without the complexity and cost of re-imaging optics. In fact, this approach allows for simple butt-coupling efficiencies of over 90%. Furthermore, the relatively large diameter of the output mirror (40 µm) eliminates the possibility of diffraction losses as the beam exits the cavity. As a result, a single device can launch several milliwatts of single mode power into a single-mode fiber (see Figure 2).

Figure 2. Light output at 1550nm as a function of incident 980 nm pump power. Over 3.5 mW of power can be coupled into a single-mode fiber.

Because the cavity length is measured in microns, the longitudinal mode spacing of the cavity is similar to the gain bandwidth of the VCSEL. Consequently, this device can only support a single longitudinal mode. Smooth tuning of this single mode output is also remarkably simple. The output coupler is supported on a deformable conductive membrane, electrically isolated from the rest of the device by a non-conductive "stand-off" ring. Application of a small voltage (a few tens of volts) between the membrane and an electrode layer on the substrate results in an attractive electrostatic force. This causes a contraction of the effective cavity length and tuning of the output wavelength.

Part II of this story will discuss performance, volume manufacturing, and applications.

About the author…

Daryoosh Vakhshoori is chief technical officer and Don McDaniel is product manager at CoreTek, Inc. 25 B Street, Burlington, MA 01803. Tel: 781-273-2005; e:mail: mcdaniel@coretekinc.com.