Sensor Influence On The Precision Of Piezo Positioning Stages

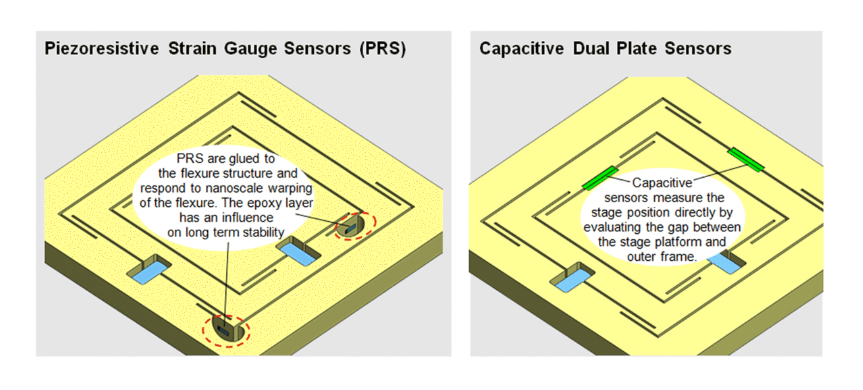

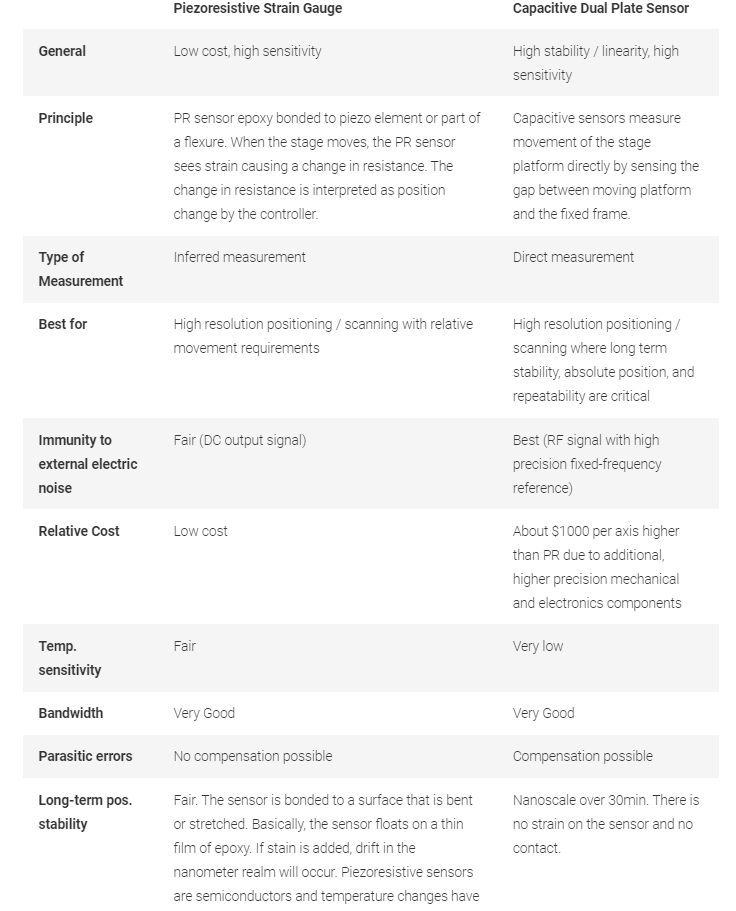

The choice of feedback sensor is one of the key performance factors of a piezo positioning stage. Below is a comparison between the two most commonly used sensors. When the absolute positioning information plays a critical role in scientific results, researchers prefer capacitive sensors. When cost is most important and / or results are based on relative position, the more economical piezoresistive sensors are just fine.

PI provides stages with both options plus a variety of other sensor choices as well, depending on parameters such as sensitivity, stability, dynamics, cost, etc. It is important to understand the application and how the positioning performance affects the results to recommend the sensor best suited to the application.

In addition to the sensor type, the controller concept also has a strong influence on performance parameters, such as settling, linearity, and bandwidth. Two basic controller types are commonly used with piezo nanopositioning systems: classical, analog servos (can have a digital command interface) and digital servos (can also have analog command interface). Learn more on analog and digital servo controllers.

Comparison of Piezoresistive and Capacitive Dual Plate Sensors

Stability Record

A new stability record with sub-nanometer drift was recently achieved by the National Institute of Standards (NIST). The published article describes a complex dual laser beam-based measurement system. The experiment setup employs an XYZ piezo stage with capacitive position sensors, model P561.3DD from PI.