Selecting The Right Deformable Mirror — Part 1: Imaging

By Michael Feinberg, director of marketing and sales, Boston Micromachines

Choosing the right deformable mirror can be challenging with the extensive options available these days. In this article, I will explore some of the basic questions you should ask in order to help determine which type of deformable mirror is best suited for a given application. This list is by no means exhaustive, but if one has an understanding of these topics, the journey to creating spectacular images and accurately shaped beams will be much smoother and equally as rewarding. In this two-part series, I am starting with imaging, since this is a field that is constantly expanding to new disciplines and often involves researchers who are not familiar with adaptive optics. In part two of the series, I will discuss choosing the right deformable mirror for beam shaping applications.

Potential customers come to us at Boston Micromachines looking to design adaptive optics systems for many different applications (e.g. confocal microscopy, conventional microscopy, astronomy, etc.). However, many of those customers do not know their options when selecting the right mirror. We believe the questions you need to ask involve these four simple topics.

1) Aperture: How big is your image? How big (or small) can you make it?

The size of the wavefront is the first and foremost issue to understand. Some applications have no control over this, while others can change the size of their wavefront through the use of some simple telescoping/focusing optics. Before doing research into your alternatives, you should figure out what your limitations are in relation to aperture.

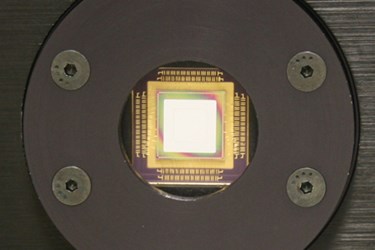

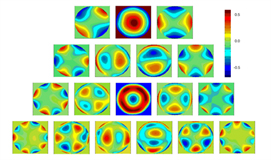

Measured surface of a MEMS deformable mirror with various Zernike profiles

2) Resolution: How complex are your aberrations?

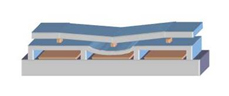

Having the right aperture is great, but if your mirror does not have a high enough level of resolution, your image improvement will be significantly limited. When referring to displays, this is essentially pixel size. In the deformable mirror industry, we call the distance between control points, "pitch." In our devices, it is the distance between actuators. In membrane-type mirrors, it will be the distance between electrodes that are underneath but not directly connected to the surface.

Profile of MEMS deformable mirror structure

If your aperture can be manipulated, the precision to which you can control the wavefront will most likely be directly affected by this adjustment. Also, the pitch can affect the price of the mirror. Understanding what the relationship is between aperture, pitch, and price can help you not only find the right mirror, but minimize your costs.

3) Aberration: How big (deep) are your aberrations?

While aperture and resolution cover you in two dimensions, depth is the last critical physical dimension. The size of your aberrations will directly impact the necessary stroke (the distance the surface of the mirror can travel up and down). If you have very small aberrations and require a high level of precision to correct your wavefront, you can focus on MEMS-based solutions, like those provided by Boston Micromachines (available stroke is between 1.5 and 5.5 um). However, if you require larger stroke, you may need to focus on more flexible electromagnetic or piezo-electrically motivated membrane surfaces.

Some have executed what we call a woofer-tweeter approach, where a larger mirror corrects for the larger aberrations (the woofer) and a smaller, more precise mirror fine-tunes the image (the tweeter).

The size of the aberrations is a crucial point to understand due to the fact that if you do not have enough stroke or a high enough level of precision, your image may not improve enough to be impactful.

One important point to keep in mind when characterizing your aberrations and relating them to the necessary stroke: Remember that when the mirror moves a given distance, it is actually affecting the phase of the light by two times the distance moved. So, for example, if you have aberrations in your light of various amounts up to 3 um, you only need 1.5 um of stroke to compensate for this.

4) Response: How fast do your aberrations move?

If you're dealing with a static medium, then response is not an issue. However, if you are dealing with atmospheric turbulence, as in astronomy, or in vivo conditions in live specimens, then response is a vital parameter. While this is dependent on the structural composition and design of the mirror, it is also dependent on the drive electronics and controller. Make sure that both your system (PC or other controller) and the electronics associated with the mirror are up to snuff for your application.

As mentioned before, this list is not exhaustive, but if you have these initial questions answered you will feel more confident in your purchase. If your application is geared towards laser beam shaping, be on the look out for the next part of our series.

Michael Feinberg is the director of marketing and sales at Boston Micromachines Corporation. Michael currently oversees all product sales, marketing, and business development activities.

For more information, please visit www.bostonmicromachines.com.