'Rectenna' Works At Optical Frequencies

Made from a forest of modified carbon nanotubes, a "rectenna" has been used for the first time to convert visible light directly into electricity.

The device combines the signal-capturing properties of an antenna with those of a rectifier, which converts alternating current into direct current. Rectennas that function at wavelengths of more than 10 μm have been demonstrated as early as the 1960s, but comparatively shorter wavelengths have made it impossible to translate the technology to visible light until now.

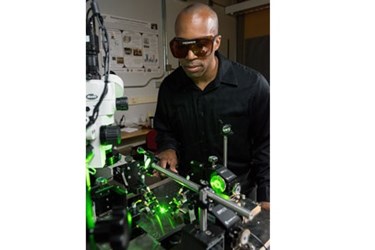

"The physics and the scientific concepts have been out there," said Baratunde Cola, a professor at the Georgia Institute of Technology who led the research. "Now was the perfect time to try some new things and make a device work, thanks to advances in fabrication technology."

Optical rectennas could provide a new technology for photodetectors that operate without the need for cooling, for energy harvesters that could convert waste heat to electricity — and ultimately for a new way to efficiently capture solar energy.

In the devices, carbon nanotubes act as antennas to capture light from the sun or other sources. As the waves of light hit the antennas, they create an oscillating charge that moves through rectifier devices attached to them. The rectifiers switch on and off at record-high petahertz speeds, creating a small direct current.

Billions of rectennas in an array can produce significant current, though the efficiency of the devices demonstrated so far remains below 1 percent. The researchers hope to boost output through optimization techniques and believe that a rectenna with commercial potential may be available within a year.

"We could ultimately make solar cells that are twice as efficient at a cost that is 10 times lower, and that is to me an opportunity to change the world in a very big way," Cola said. "As a robust, high-temperature detector, these rectennas could be a completely disruptive technology if we can get to 1 percent efficiency. If we can get to higher efficiencies, we could apply it to energy conversion technologies and solar energy capture."

Fabricating the rectennas begins with growing forests of vertically aligned carbon nanotubes on a conductive substrate. Using atomic layer chemical vapor deposition, the nanotubes are coated with an aluminum oxide material to insulate them. Finally physical vapor deposition is used to deposit optically transparent thin layers of calcium then aluminum metals atop the nanotube forest.

The difference of work functions between the nanotubes and the calcium provides a potential of about 2 eV, enough to drive electrons out of the carbon nanotube antennas when they are excited by light.

In operation, oscillating waves of light pass through the transparent calcium-aluminum electrode and interact with the nanotubes. The metal-insulator-metal junctions at the nanotube tips serve as rectifiers, switching on and off at femtosecond intervals, allowing electrons generated by the antenna to flow one way into the top electrode. Ultralow capacitance, on the order of a few attofarads, enables the 10-nm-diameter diode to operate at these exceptional frequencies.

Source: Georgia Tech