PV Nano Cell Enters U.S. Market With Innovative Inkjet Solar Cell Printing Technology

PV Nano Cell (Migdal haEmek, Israel) an innovative single-crystal nano-metric conductive digital inks producer, on April 9th, 2015 announced its plans to enter the U.S. solar photovoltaic (PV) market with its “Sicrys” silver and copper inks.

The inks will reduce the cost of silicon solar cell production, using an efficient process that produces sustainable inks without the use of hazardous wastes, and by increasing solar cell efficiencies at a mass production scale, the company emphasizes.

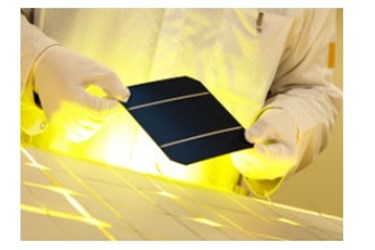

Conductive inks are used in the manufacture of solar cells, which are the building blocks of solar PV panels. The solar cells are printed with conductive grid lines that capture the electricity generated when sunlight strikes a solar cell. With the solar industry under enormous pressure to speed acceleration by reducing costs while continuing an environmentally responsible production process, the search is underway for new printing technologies that reduce the costs of producing solar cells and increase solar cell efficiency, thus allowing more energy to be harvested from each cell.

“The cost of solar has dropped dramatically, but it will have to come down even further if it is ever to make up a significant share of the U.S. energy supply,” said Fernando de la Vega, Ph.D., founder and CEO of PV Nano Cell.

“As we eagerly enter the U.S. market, we are confident that our “Sicrys” nano-metric conductive inks will have a significant impact on reducing costs and increasing efficiency in the solar industry, at a scalable level for international manufacturers, thus stimulating growth and accelerating the rate of adoption.”

Inkjet printing replaces traditional screen printing

PV Nano Cell’s Sicrys silver nano-metric conductive inks reduce costs because they can be used with innovative noncontact digital inkjet printing, instead of traditional screen printing. Because it does not involve contact with the cell, inkjet printing reduces the amount of cell breakage, reducing the wastage of costly silicon; in addition, it also enables the use of thinner wafers, which also saves on silicon costs. Silicon, the expensive semiconductor material used in solar cells, represents 75 percent of the cost of a solar cell.

Silver consumption reduction can reach up to 70 percent

Implementing Sicrys silver nano-metric inkjet inks in the metallization of silicon solar cells allows manufacturers to reduce the amount of silver needed in the cell. Depending on the cell set up, the level of silver consumption reduction can reach up to 70 percent, saving on the cost of silver, which is the most expensive material used in the production of solar cells.

PV Nano Cell’s inks are also “green,” meaning that they are produced without hazardous waste – an important differentiator as the environmental consequences of solar panel manufacturing, including the dumping of toxic waste, come under increased public scrutiny.

In looking to the future, PV Nano Cell inks can also be used in organic photovoltaic (OPV) cells, or solar cells made from carbon-based molecules, which are being developed as lightweight, flexible, low-cost alternatives to rigid silicon solar panels.

In addition to its silver inks, which are standard in the solar industry, PV Nano Cell has also developed the world’s first commercially available, stable copper nano-metric inkjet conductive inks, which deliver the properties of its Sicrys silver inks with even greater cost efficiency based on a significantly lower cost for the metal, the company emphasizes.

Source: PV Nano Cell