MEPhI Scientists Find Way To Raise Energy Efficiency Of Lighting Facilities

Solid-state light sources most economically use energy in comparison with preceding generations of electric light sources – arc lamps, incandescent and discharge lamps. The elementary unit of modern solid body lighting systems is white light-emitting diode – it is usually a “blue” chip, covered with a layer of amber phosphor, which “absorbs” a part of blue radiation and re-irradiates it in the amber field of the spectrum.

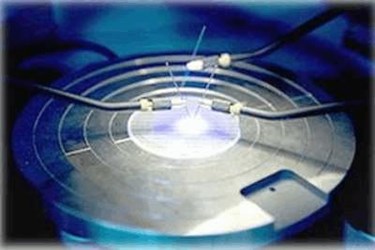

In the LED production one or several chips are mounted on a special card. Chip-setting at the card can be conducted in two ways: on-line editing and so-called flip-chip method. The gist of the flip-chip process is the connection of semi-conductor structure with the carrier active side down. The main advantage of the flip-chip method is refusal from bonding wire using, enhancement of the packing density, possibility of mounting at flexible carriers.

The perfection of solid-state light sources is impossible without the development of effective LEDs. One of the main problems in the creation of high-radiance LEDs is the low coefficient of the light output from crystal. Due to the big difference in the refraction index value according to the Snell law of refraction the significant part the generated radiation is reflected inside at the border line semiconductor-air and semiconductor-baseplate in “flip-chip” editing, and only a small part penetrates outside.

Application of base coats from Silicon Carbide SiC with high refraction index, close to the refraction index of GaN, allows get rid of the total internal reflection phenomenon at the semiconductor-baseplate border line because of suppressing of the waveguide effect. Currently the most effective way of overcoming this problem is the creation of light-dissipating surfaces.

That’s why the aim of work, conducted by MEPhI “Nanotechnologies” Centre, was the pattern formation at the surface of Silicon Carbide by the plasma-chemical etching method, for enhancement of external quantum efficiency of blue light-emitting diodes on the basis of InGaN/GaN heterostructures.

In the dry etching process the bottom side of the base coat 4Н-SiC was covered with micro- and nanorelief with netty form of texture. The sizes of texture elements varied from 3´3 square um at a distance of 2 um between them. Measuring of the light output power showed that in comparison with LED, not having texturing, all crystrals with textured baseplate having a 1.5-2 times higher light efficiency. What’s more, the light efficiency depends on sizes of inhomogeneities, and LEDs, having size of texture elements 400-500 um, are characterized by the highest quantum output. It is qualitatively explained not only by light diffused scattering at the obtained nanorelief but also by forming cut zones for radiation diffusion along the surface.

“The developed technology of getting SiC relief surface can be used in conditions of flip-chip LEDs’ full-scale production. Its incorporation will significantly raise energy efficiency of Russian light devices,” commented one of project participants, MEPhI IFNE Deputy Director Alexander Gusev.

Source: National Research Nuclear University MEPhI (Moscow Engineering Physics Institute)