First Tunable Diamond Raman Laser Developed

By Jim Pomager, Executive Editor

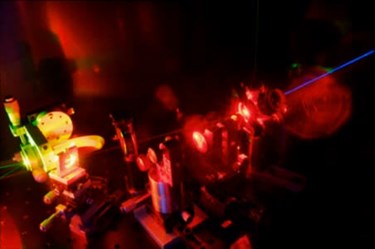

Researchers at the University of Strathclyde’s Institute of Photonics (Glasgow, Scotland) have developed the world’s first tunable diamond-based Raman laser, capable of producing a broad range of output wavelengths. The device — also the first-ever continuously operating diamond Raman laser — could lead to more targeted treatments for skin and eye disorders, as well as improvements in pollution monitoring and aeronautical engineering.

Advantages Of Diamond

Diamond has several advantages over silicon and other conventional crystal materials, particularly when it comes to laser tuning. In addition to its excellent strength and rigidity, diamond also delivers high Raman gain and has a broad optical transmission range, meaning it is capable of generating a wider array of wavelengths.

The Strathclyde researchers capitalized on these unique optical properties in their new laser design. By incorporating diamond crystals into semiconductor disk lasers, they were able to create a novel tunable laser capable of generating an unprecedented range of wavelengths. “Our new lasers can generate light ranging from the lower end of the ultraviolet part of the electromagnetic spectrum, right through the visible part, up to the middle of the infrared region,” said Martin Dawson, the professor who oversaw the research.

Some of the wavelengths produced by the new diamond Raman laser are hard to achieve by other means yet are essential in many important applications. For instance, wavelengths in the yellow-orange spectral region (which spans from approximately 570 to 625 nm) have proven very successful in treating vascular lesions, abnormal clusters of blood vessels directly under the skin, since they are readily absorbed by the lesion but not by the surrounding tissue. Yellow-orange light is also used in the treatment of retinal hemorrhaging (bleeding) in the back of the eye.

Another area in which diamond outshines silicon and other crystals is its ability to conduct heat. By leveraging this superior thermal conductivity, the new Strathclyde laser can achieve high power levels using a diamond crystal only millimeters in length, while a conventional Raman laser would require a crystal that was several centimeters long. For the OEMs who will eventually implement this technology in their designs, the obvious benefit is a reduced device footprint.

“[The smaller crystal size] means lasers could be deployed in confined spaces where they currently simply can’t go — such as in aeronautical applications and medicine where high-power lasers of particular colors are required but space is at a premium,” Dr. Alan Kemp, principal investigator on the project, explained.

Another First: Continuous Wave Tuning

In addition to being the first tunable laser of its kind, the Strathclyde technology is also the first continuously tunable — or continuous wave (CW) — diamond Raman laser. CW is preferable to pulsed operation in many applications, including medical treatment of highly sensitive areas of the body. Pulsed lasers cause excessive acoustic disturbance that can damage the delicate structures in the eye, for example (as in laser surgery to treat retinal hemorrhaging, as discussed above). Not so with a CW laser.

No Ordinary Diamond

While the crystal used in the Strathclyde laser was, in fact, a diamond, it was by no means your standard natural diamond. To obtain a single-crystal diamond imbued with the exact optical properties required for the project, the research team turned to Element Six, a synthetic industrial diamond supplier and part of the De Beers Group. The two organizations have been working together on diamond materials since 2005.

Using its proprietary microwave chemical vapor deposition (CVD) process, Element Six grew what was essentially an impurity-free crystal (heat spreader and transparent window) that met the following requirements of the Strathclyde research:

- Very low absorption, allowing for the higher power outputs discussed above

- Low birefringence (as low as Δn<10-6), reducing light scattering and improving laser efficiency

- Larger dimensions, required for Raman applications

- Extremely flat and smooth surfaces, for ease of coating and bonding materials

- Cutting specific angled surfaces onto the optical parts (e.g. at the Brewster angle), to increase optical efficiency

Finding a natural diamond with these characteristics would have been next to impossible — and extremely expensive. Other reasons why CVD diamonds proved a perfect fit for the Strathclyde team include its broad range of wavelengths (from 220 nm to >50 μm), high thermal conductivity (up to 2200 W/m.K, highest of any material at room temperature), and availability (for potential commercial applications).

Bright Future For The Technology

Based on the recent breakthroughs and continuing efforts of the Strathclyde group — as well as parallel research into diamond Raman lasers led by Rich Mildren at Macquarie University (which also uses CVD diamond material from Element Six) in Sydney, Australia — it’s clear that this new class of lasers has a bright future in medical, aerospace, and environmental design. OEMs that incorporate lasers into their designs for such applications would be wise to follow the ongoing development of this exciting technology.

For more information and additional images of the Strathclyde laser and researchers, check out this video:

Editor’s note: The University of Strathclyde research is being funded by the Engineering and Physical Sciences Research Council.

Photo credit: Graeme Fleming, University of Strathclyde