Zygo Accumold Case Study

Accumold relies on ZYGO coherence scanning interferometer equipment to maximize efficiency.

Overview

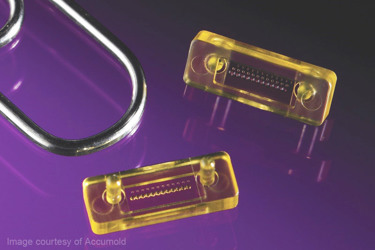

Accumold is a pre-eminent micro molding company experienced in fabricating precision micro, small, and lead-free injection-molded plastic components.

To achieve the exacting standards that its customers require — often making safety critical components smaller than a grain of sand — validation is a crucial area for Accumold. So they’ve partnered with ZYGO to enhance their more demanding measurement and validation work.

For Accumold, metrology is critical at all stages of the micro molding process, and so it moves from being a necessary evil to enabling technology. Metrology assists in the improvement of the design of parts and in making components that are easier to mold, easier to measure, and which perform optimally in end-use applications.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Photonics Online? Subscribe today.