CNC Milling Capabilities

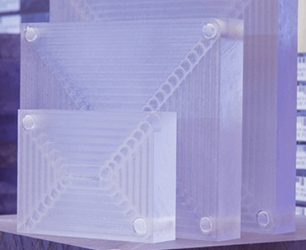

The Proto Labs CNC milling process is a subtractive manufacturing process that utilizes multiple toolsets based on efficient cutters for a specific plastic or metal material. A machine will then rapidly mill parts out of the block with either 3- or 5-axis milling. Custom prototypes and end-use production parts can be created in as fast as one day.

The machined plastic parts can be left as-milled, and typically show visible took markings. Options for more finishing choices are available for some metal parts. Once a surface finish is applied, parts are boxed and shipped shortly afterwards. More than 30 production-grade plastic and metal materials are in stock and are suitable for various applications and industries. Typical materials include plastics like ABS, polycarbonate, nylon, and PEEK to aluminum, stainless steel, magnesium, and copper metals.

For more information on Proto Labs’ CNC milling capabilities and guidelines, visit the Proto Labs webpage.