SWIR Cameras Can See Through Crude Oil

By Xenics

The behaviour of small water drops falling through a viscous oil, can be investigated by using a SWIR camera. In the infrared spectrum from 900 to 1700 nm, any crude oil is nearly transparent. Why should one be interested in looking at water drops in oil?

Introduction

Irrespective of whether it is on the Norwegian continental shelf, in Brazil or in Saudi Arabia, what is produced from an oil reservoir will be a mixture of oil, gas, water and sand. For some heavy oils in tar sands, steam is used in the recovery process to reduce the viscosity. This results in oil‐water mixtures and processing is required before the oil can be sold to a customer, either as a natural gas for use in residential houses or gaspower plants or as oil for production of petrol or diesel.

The density differences between oil, gas, water and sand are used to separate these four main components:

- Gas can easily be separated because of a large density difference;

- Sand can precipitate and become a sediment;

- Oil and water have a smaller density difference and will need more time for separation.

The efficient separation of oil and water clearly is the biggest challenge here.

Separation Of Oil And Water

Large settling tanks (particularly cumbersome on offshore platforms) are needed to allow the time-consuming gravitational sedimentation of water droplets. In order to speed up the overall separation process, different techniques promoting droplet growth have been developed. Electrostatically induced attraction and merging (electrocoalescence) of droplets has demonstrated unmatched capabilities.

Electrocoalescence And How To Further Optimize The Process

By activating electric fields in oil‐water mixtures, small water droplets will be attracted to others and form larger drops. This makes the oil‐water separation process more effective as larger drops settle faster than smaller droplets. This process is called electrocoalescence.

Experience has proven that this technique works, however, the details about what will happen when two drops coalesce are not completely understood. Due to the large variation in crude oil quality and due to the simple fact that visual studies of water drops in dark crude oil are impossible with visual high speed cameras, it is difficult to optimize the process in terms of turbulence degree, size and frequency of the electric field. Studies in transparent oil are unsatisfactory as the real problem is crude oil in general.

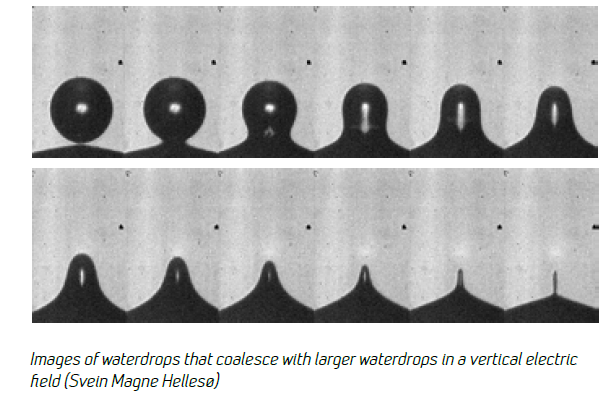

A high speed SWIR camera (Cheetah CL), sensitive in the 900 to 1700 nm range, can see through the oil and find out what happens when two water drops collide and coalesce in a dark heavy oil. The water absorbs most of the SWIR photons and will appear as dark drops in a lighter surrounding medium (oil). A high speed camera is required as the time between two drops touching and becoming one larger drop is typically less than 40 ms.

A high speed SWIR camera (Cheetah CL), sensitive in the 900 to 1700 nm range, can see through the oil and find out what happens when two water drops collide and coalesce in a dark heavy oil. The water absorbs most of the SWIR photons and will appear as dark drops in a lighter surrounding medium (oil). A high speed camera is required as the time between two drops touching and becoming one larger drop is typically less than 40 ms.

With clear, high speed SWIR images of water drops colliding in oil, researchers are now able to compare experimental results in different qualities of heavy oil under a variety of temperatures with mathematical model calculations of equivalent effects.

Conclusion

A high speed SWIR camera (Cheetah CL) has proven to be a very valuable tool in electrocoalescence research for water separation from heavy crude oil. The Cheetah CL camera can obtain well above 1000 frames per second at 640x512 resolution, enabling a detailed investigation of the high speed water drop coalescence process in visually non‐transparent crude oil.