Designing Lens-Free Microscopes Based On Holographic Imaging

Richard Stahl, Geert Vanmeerbeeck, imec

Leading nanoelectronics research center imec has recently developed a new microscope — a fast and compact, lens-free imaging solution based on holographic imaging. Starting from a well-known R&D concept, imec’s engineers made a robust solution that can be fabricated by tool providers and used in commercial labs and industrial environments. Imec’s solution is characterized by a very large field of view, high resolution, fast reconstruction software, and excellent scalability. It offers the prospect of easy integration in bio-incubator environments, in large-surface inspection, and even in micro-sized lab-on-chips.

The Basis: Holographic Imaging

Lens-free holographic microscopy is a technique that can yield images with a resolution of 1 μm or below over a field-of-view that is orders-of-magnitude larger than traditional microscopes. Moreover, the image capturing and interpretation is completely digital, eliminating any need for manual intervention, mechanical calibration, or focusing.

Holography, the principle behind lens-free imaging, was first formulated by the Hungarian-born engineer Dennis Gabor in the late 1940’s. For perfect imaging, he reasoned, you need not only the amplitude of light, but also phase information (which gives you thickness and depth information). He proposed to capture – on a photographic plate – the interference pattern between the light that illuminated an object and the light that diffracts of an object. In this hologram, all information is available to reconstruct a perfect image of the object.

Only recently, with the advent of powerful CCD- and CMOS-imagers, Gabor’s photographic plates could be replaced with a fast, high-resolution digital image sensor. And computers have become powerful enough to do image processing within a reasonable time. So now, it has become practical to convert the captured holograms into useful images by calculation instead of illumination. This was what labs around the world needed to start experimenting with lens-free holographic microscopy as a replacement for and an extension of traditional microscopes.

Figure 1 — Prototype lens-free microscope made at imec

Building A Versatile Microscope

With its track record in specialty image sensors and electronics integration, imec also set out to develop lens-free microscopy, but with a special aim. From the start, we were looking to make an industrial-strength solution — a solution that could be mass-produced and integrated in tools that allow fast microscopic inspection of large surfaces.

There is much interest in such tools in the world of display manufacturing where forever larger displays are produced with ever smaller pixel sizes. Here, automated inspection may still slow down the manufacturing speed because of all the mechanical movements needed by microscopes with a small field-of-view. Therefore, inspection by trained people is sometimes preferred over automated inspection.

Another notable domain where lens-free solutions bear great promises is biotechnology and life sciences. Imec has a large team doing advanced R&D in this domain. And the more these experts get experience with integrating, micro-sizing, and automating tools, the more they get interested in lens-free imaging.

What attracts them is the possibility to inspect living, transparent cells to monitor cultures and tissues thanks to the large field-of-view, and to automate cell identification and inspection with smart image processing.

These features make a lens-free microscope a better-suited tool than traditional microscopes for a number of applications, such as inspecting stem cell colonies or in-vitro monitoring of heart cell contraction. In addition, lens-free technology is also a promising road for use as an on-chip microscope integrated in future lab-on-chip technology.

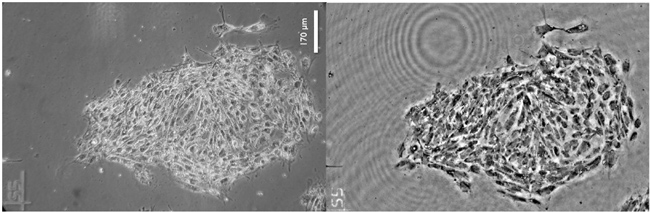

Figure 2 – Stem cells seen through a phase contract microscope (left) and through imec’s lens-free microscope (right)

Robust Prototypes For Life Sciences

The principle of a lens-free microscope using inline holography is simple: take a coherent light source (e.g. a laser) and shine it through the transparent sample. Then record on a digital image sensor the interference between the light that has gone through the object and a reference beam (i.e. the original light beam). And lastly, reconstruct the image for visualization and information extraction. This setup only requires a light source, an image sensor, and a powerful processor to compute the images in near real-time.

In such a lens-free system, the field-of-view depends on the size of the image sensor. For our first microscopes, we selected a state-of-the-art monochrome 10 Mpixel imager with 1.67 μm pixel pitch, and a fiber-optics coherent light source. With this setup, we obtained a field-of-view of about 30 mm².

Such a large field-of-view is especially useful in cell culturing applications, where automated growth monitoring is needed. But at the same time, the resolution should be so good that it is possible to observe single cells, cellular outgrowths, and density variations in the colony.

Inline holographic recording on an image sensor suffers from an inherent distortion. This can be reduced by an iterative recombination of a number of slightly different input images, a technique known as iterative phase retrieval. In our case, we implemented an innovative approach using a series of images each illuminated with a slightly different wavelength.

By carefully co-optimizing the imaging hardware, reconstruction software, and illumination optics, and by using a multi-wavelength light source, we arrived at a robust lens-free image acquisition system with a 1.23 µm resolution, similar to the resolution of a phase-contrast microscope with 10x objective, but with a field-of-view that is 14 times larger.

To Catch A Heart Cell Contracting

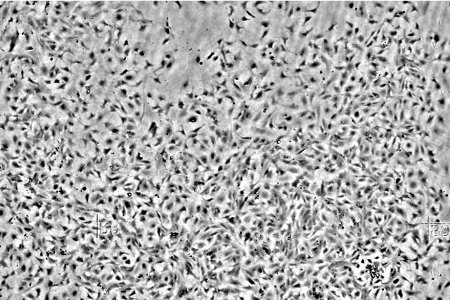

A second application we looked at is in-vitro drug testing. Currently a hot topic in drug discovery is to try and test potential new drugs on cells and tissues grown in the lab (e.g. on layers of heart cells).

But to monitor contracting heart cells and follow the speed of conduction from one cell to the next in a monolayer of cells, you need to look at the changing shape of a relevant number of cells. So, you need a very large field-of-view, but you don’t necessarily need to see all the details of the cells.

And to see the changes in contraction – which may be subtle – you need a high imaging speed. This speed, of course, depends on the speed of the image sensor, but also on the speed with which the pictures can be digitally computed, either in real-time or with post-processing. So for high-speed setups, we had to optimize both our computation and our hardware setup, using a combination of CPU and GPUs. In this setup and using post-processing, we managed an imaging speed of almost 300 frames per second, with higher speeds possible.

Heart cells contract when they receive a high enough electrical stimulus from a neighboring cell. But drugs can interfere with that reaction. So another challenge was to measure the relation between the contraction of a heart cell and the electrical stimulus. To do that, our researchers grew the cells on a chip with an array of microelectrodes. However, these surfaces are not transparent. So it is not possible to shine light through a sample and capture the result at the other side, as we did in our first setups.

For this new setup, we reverted to an innovative use of reflective holography, where the hologram is made from the interference of the reference beam with the light that reflects off an object (instead of the light that shines through the sample).

Figure 3 — Cardiac cell culture (horizontal view approx. 2 mm)

A New Paradigm In Microscopy

These are only two of the applications we’re currently looking at. Another promising road is to micro-size the setup for use inside lab-on-chips. This solution will be CMOS-compatible and will use microfluidics and integrated photonics for the light source and imager.

With the exciting evolutions in biotechnology, we see many of our industrial partners, reputed companies involved in microelectronics or biotechnology, looking into this technology and challenging us to try and match our microscopes with their applications. As one of the only R&D labs with design and fabrication capabilities, our engineers are able to implement and integrate application requirements into working prototypes.

The results are compact solutions, mechanically robust, with little or no system recalibration or realignment, and requiring no maintenance. They can be easily scaled to a multi-microscope system with very large field-of-view. This is crucial to upscale stem cell production, lowering its cost and enabling more therapeutic applications. That way, lens-free microscopes can be a new building block for innovative biotechnology applications, allowing these to grow to a level that would not be possible with traditional microscopy.

Figure 4 — From image acquisition to application-dependent analysis and visualization